3000L powerful ultrasonic cleaning diesel heavy duty cylinder heads and engine parts

Marine engine repair, manufacture, and sales companies can rely on ultrasonic cleaning technology to remove dirt and contamination so that vessels run better and more efficiently. The marine environment is tough on large and small engine components, but ultrasonic maintenance works on even the most fragile parts. Ultrasonic cleaning is safer for the environment, faster, limits vessel down-time, and extends the life of costly equipment.

We know that the cleanliness of the parts you process reflects on your business and reputation. Count on us to provide the tools, training, and support you need to maximize your production and profitability.

AG SONIC manufactures an ultrasonic auto parts washer that is designed to remove the stubborn contaminants such as burned carbon, oils and greases, metal chips, and other dirt found in auto and aviation rebuilding shows.

Brief introduction:

We rely on specialized machinery to clean the engines of ships and other vessels, including marine fuel injector cleaning. For this reason, we use the best ultrasonic technology developed for its application in a multitude of industries, such as the automotive or marine industry, managing to achieve top results in all of them, and offering a planned maintenance system for ships. This is the result of years of work and research to offer our clients an effective solution to marine maintenance, compatible with every type of industrial processes. Marine ultrasonic cleaning machines using an ultrasonic cleaner are the best option for ship maintenance and for all sort of elements. Furthermore, large-scale machinery, manufactured with high-resistance materials is specially designed to support heavy loads. AG SONIC will not have any further problems with the ultrasonic cleaning of ship engines.

Discover the power of the cavitation process created by ultrasound equipment. The generation and implosion of bubbles in an aqueous medium allows the absolute elimination of waste in all the surface of submerged parts, maintaining the base material. Furthermore, the ultrasound equipment stands out for the efficiency of his operation, achieving fantastic results with low energy consumption. Optimize the industrial process and increase the quality in the final result of the parts. Allow the perfect cleaning of a ship engine, as well as other parts such as marine fuel injectors with the leading-edge technology offered by AG SONIC. Our professionals have broad experience and will provide you with the best advice. We specialize in the development of customized projects for all kind of industries. Please contact us and request specific information. We will be delighted to assist you.

Wide Application:

Ultrasonic cleaning can be used for many applications, including plastic parts, bearing, bolts, rubber parts, internal parts, plastic injection molds, transmission parts, and final cleaning of all engine parts prior to assembly, the versatility of ultrasonic cleaning machine make them the perfect choice for automotive, medical, pharmaceutical, aerospace, engineering and many other industries.

Product features:

High power transducer cleaning effect significantly, usable macroscopic observation;

After cleaning objects shine light;

Digital LCD control boot time;

The stainless steel and the lid, bladder, more upscale;

Waterproof properties is greatly improved, more safety products last;

With constant temperature system with heating.

Pls find more specifications below:

| Specifications for ultrasonic cleaner T-288S |

| Model |

T-288S |

| Tank capacity |

1800L |

| Tank size |

L150xW150xH80cm |

| Tank material |

2mm SUS304 |

| Ultrasonic power |

14.4KW |

| Heating power |

30KW |

| Timer |

1-99min adjustable |

| Heater |

0-80c adjustable |

| Frequency |

28/40khz |

| Control |

External generator, more stable |

| Optional |

Oil filter system, pneumatic lift, rinsing tank, etc. |

| Voltage |

110V, 1phase; 220V, 3phases/220V, 1phase; 380V, 3phases |

| Warranty |

1 year |

| Packing |

1unit/wooden case |

Packing and Shipping:

| Packing , loading, delivery time |

| Packing unit |

1set/wooden case |

| Packing method |

Export wooden case |

| Loading port |

Shenzhen |

| Delivery time |

About 15 working days |

| Minimum Order Quantity |

1set |

| Transport method |

By express company / air / sea |

What do I need to consider when purchasing a large ultrasonic cleaner?

When dealing with large liquid volumes and ultrasonic cleaners, there are several considerations:

- Tank Integrity: The tank needs to be able to withstand the pressure of the liquids and the weight of the parts being cleaned. This requires a specific tank design that moves the stress points away from welded edges.

- Ultrasonic Power: There needs to be enough ultrasonic power to provide the cleaning performance you need.

- Ultrasonic Frequency: The frequency chosen will usually be in the low frequency range when cleaning heavy parts, or AG SONIC Multiple Frequency Ultrasonic System operating at 25 and 40kHz.

- Heating Systems: Large tanks may require extended time to heat to operational temperatures due to the large liquid volume in the tank.

- Filtration Systems: Need to be large enough to remove the dirt being removed from the parts, and push to dirt towards to filter system suction port. Filter housings and pumps need to be larger.

- High-volume Oil Skimming: When removing greases and oils, a high volume oil skimmer with the ability to isolate surface oils from the cleaning tank is needed to prevent oils from re-depositing onto parts when they are removed.

How large can the ultrasonic cleaning tank be?

The only limitation is the size of your parts. Tanks from 1000-3500 gallons in size have been manufactured by AG SONIC. At 3500 gallons, a small car could fit into the tank. This gives you an idea of how large ultrasonic cleaning tanks can be. If you already have an existing tank, AG SONIC can supply immersible transducer systems to provide ultrasonic cleaning action to your existing tanks.

How many tanks do I need for my application?

If you already have a way to rinse and dry your parts, you would need only a single ultrasonic cleaning tank sized to fit the load of parts you intend to clean. If you need rinsing and/or drying, these tanks can be included in the system.

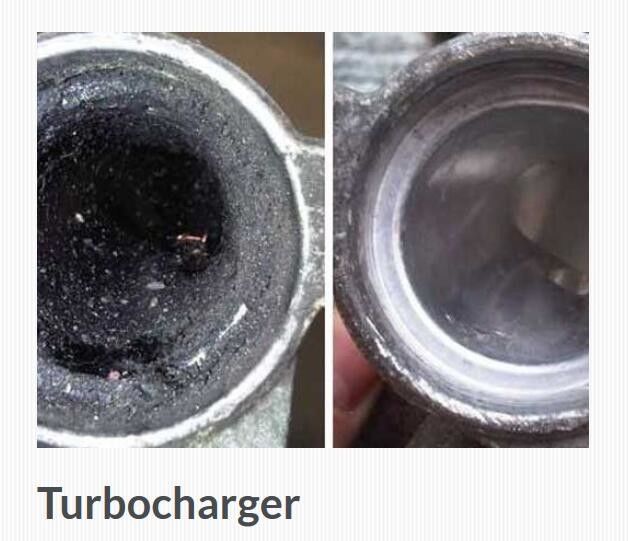

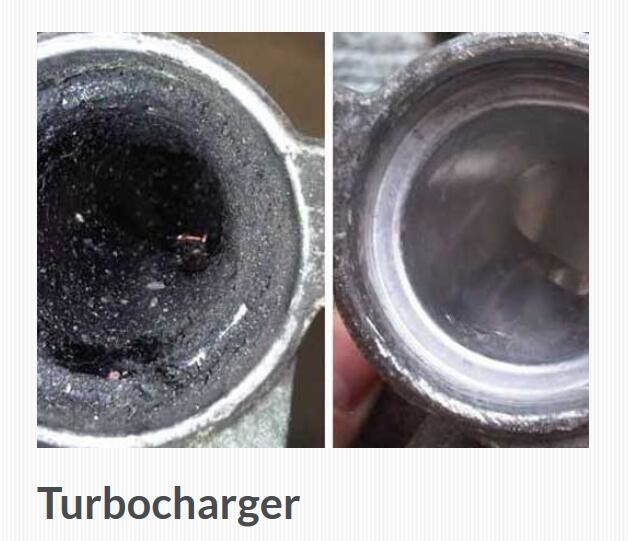

Cleaning effect:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!