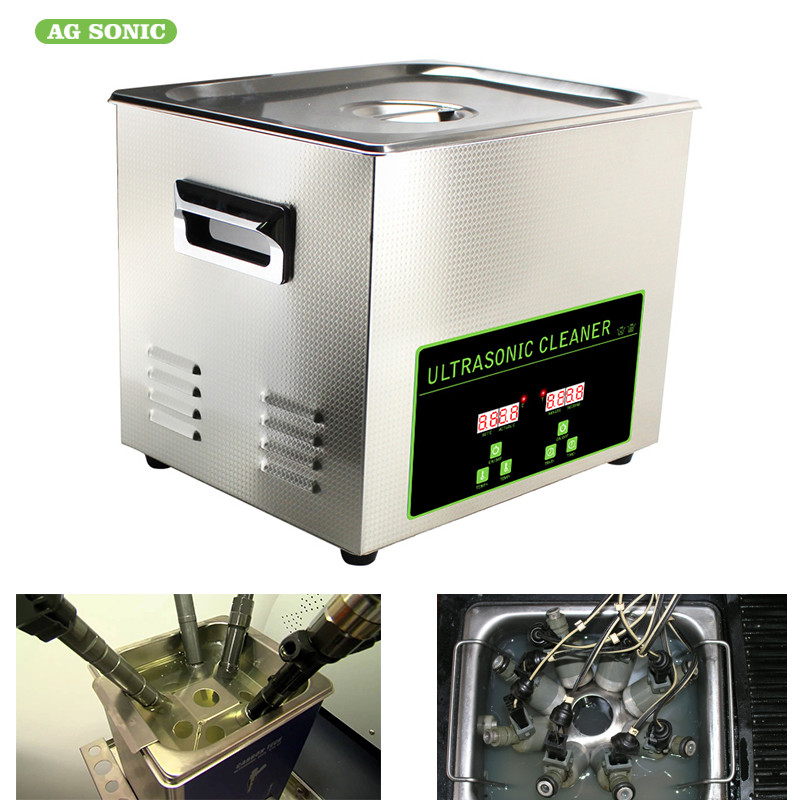

Heated Ultrasonic Cleaners With Digital Timer Industrial Parts Cleaning

Cleaning the Fuel Injectors

If the fuel injectors are restricted or leaking, there are several options to clean them including:

1. A fuel injector-cleaning chemical that is poured into the fuel tank.

Provides a noticeable difference in power and drive-ability after one use. The disadvantages are that you can’t check the spray pattern, and the filters may become plugged with contaminants freed by the cleaner.

2. A cleaner that runs through the fuel rails and injectors.

Uses stronger chemicals that the in tank cleaners. Same disadvantages as 1.

3. An ultrasonic injector cleaner and injector flow bench.

The preferred method of cleaning injectors. Cycles the fuel injectors while the fuel injector tips are immersed in an ultrasonic bath, which uses an environmentally friendly cleaning fluid to clean the fuel injectors. The flow bench portion also allows a user to perform a flow test before and after cleaning, and it allows the user to observe the fuel injector spray pattern. This method requires that the fuel injectors be removed from the engine.

What is ultrasonic cleaning?

Ultrasonic cleaning is an exceptional technique that facilitates the cleaning process. It is an exceptionally thorough process which cleans efficiently various items. This powerful process can perform very detailed work quickly and successfully remove microscopic particles from hard surfaces. External as well as internal surfaces, blind holes and crevices, can be cleaned simultaneously and uniformly. Greasy, oily and sticky parts are efficiently cleaned with an ultrasonic cleaning unit.

- Car service: Flushing carburetors, injectors, injectors, fuel filter mesh cleaning (petrol), individual parts, assemblies, and entire blocks.

- Medicine: Washing and polishing of optics, sterilization and cleaning of surgical instruments, vials, dental and pharmaceutical industries; cleaner reusable, molds.

- Engineering: Cleaning of parts, pipes, wires, etc. before finishing, machining parts and components to the preservation, processing of parts after reopening, welding, grinding, polishing, cleaning strainers in the fuel and hydraulic systems, deburring parts.

- Instrumentation: Washing and polishing of optics, precision mechanics components, integrated circuits and printed circuit boards.

Features:

1. Ultrasonic power: 0-100% adjustable

2. Time setting: 0-30min or 24 hours continuous working

3. Heating: 20-80℃ adjustable

4: Ultrasonic frequency: 28 kHz or 40 kHz

5: Material: 2mm thickness SUS304 tank for acid-proof.

6: Improved PCB design for stable and durable industrial use

7: More strong and uniform ultrasonic wave

8: With free lid and stainless steel SUS304 basket

Other models for your choice:

10L Produce Specifications:

| Model |

TB-200 |

| Ultrasonic Frequency |

40,000 Hz |

| Material |

SUS304 |

| Tank Capacity |

10.8L |

| Ultrasonic Power |

200 W |

| Heating power |

450W strong power, quick heating |

| Timer |

1-30min adjustable |

| Heater |

0-80C adjustable |

| Unit Size |

325 x 265 x 280 mm ( L x W x H ) |

| Tank Size |

300 x 240 x 150 mm ( L x W x H ) |

| Package Size |

435 x 360 x 350 mm ( L x W x H ) |

| N.W. |

7.4 kg |

| G.W. |

8.5 kg |

| Power Supply |

AC 100 ~ 120V, 50 / 60Hz

AC 220 ~ 240V, 50 / 60 Hz |

Ultrasonics: The ONLY Way to Clean with Confidence

Regardless of the source of the dirt or contamination, AG Ultrasonic Cleaning Systems are designed to accommodate a wide variety of uses in diverse industries. Fast, effective and efficient, our machines will allow you to clean virtually any type of part or component. The following is just a short list of the many different types of items that have been cleaned using our systems.

- Automotive (Car, Truck, Motorcycle) See Video Below

- Aviation (Helicopters, Aircraft and Ground Support)

- Personal Boat & Marine

- Injection Molds

- Restaurants, Bakeries & Kitchens (Oven Filters, Burners, Pots, Pans, Utensils)

- Machines of All Types

- Tools, Nuts, Bolts

- Extrusion and Deburring

- Almost anything made out of metal (ferrous and non-ferrous), plastic, vinyl, and wood.

What is the length of cleaning time?

Cleaning time will vary, depending on such things as soil, solution, temperature and the degree of cleanliness desired. Highly visible removal of soils should start almost immediately after the ultrasonic cleaning action begins. Cleaning time adjustment is the easiest (and most often misapplied) factor used to compensate for process variables. Although new application cycle duration can be approximated by an experienced operator, it usually must be validated by actual use with the chosen solution and the actual soiled parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!