Multi Tank Industrial Ultrasonic Cleaner For Car / Motor / Truck Wash Rinse Dry Ultrasonic Parts Cleaner

How the Parts Washer works

Automotive Parts Cleaning Machine

Performance, Industrial Strength, Cleansing Action

- Cleans carbon deposits from carburetors and all manner of engine parts

- Removes stubborn oil, grease, lubricants, paint, rust, and dirt (with pre-cleaning in some cases)

- ‘Aluminum Safe’

- Penetrates deep into the part and cleans holes, small apertures, and crevices

- Cleans sensitive parts like wiring and plastic without damage

- Does not require ‘line-of-sight’ for effective cleaning

- Ensures part longevity due to high degree of cleanliness

AGSONIC ultrasonic cleaners are revolutionizing cleaning methods and processes on the automotive and mechanic shop floor. Our ultrasonic cleaners clean all types of automotive, aircraft, and marine engine parts. Ultrasonic technology for cleaning parts eliminates manual labor while providing you with superior cleansing action. Most parts can be cleaned with environmentally friendly water-based solutions.

Ultrasonic cleaners work on the principle of agitating cleaning solvents using high frequency sound waves. This ultrasonic agitation creates millions of microscopic bubbles that implode releasing vast quantities of energy. This action, known as cavitation, dislodges any contaminant stuck to the surface of a part. Ultrasonic cavitation thoroughly cleans every surface in contact with the cleaning fluid.

What can be cleaned by Ultrasonic ?

Ultrasonic cleaning involves the use of high-frequency sound waves (above the upper range of human hearing, ) to remove a variety of contaminants from parts immersed in aqueous media. The contamination can be dirt, oil, grease, buffing/polishing compounds and mold release agents, just to name a few. Materials that can be cleaned include metals, glass, ceramics and so on. Ultrasonic agitation can be used with a variety of cleaning agents.

Typical applications include removing chips and cutting oils from cutting and machining operations, removing buffing and polishing compounds prior to plating operations and cleaning greases and sludge from rebuilt components for automotive and aircraft applications.

Ultrasonic cleaning is powerful enough to remove tough contaminants yet gentle enough not to damage the substrate. It provides excellent penetration and cleaning in the smallest crevices and between highly spaced parts in a cleaning tank.

Product Description

Ultrasonic cleaning machines work on the principle of agitating cleaning solvents using high frequency sound waves, the ultrasonic agitation creates millions of microscopic bubbles that implode releasing vast quantities of energy, this action, know as cavitations, dislodges any contaminant stuck to the surface of a part, ultrasonic cavitations thoroughly cleans every surface in contact with the cleaning fluid

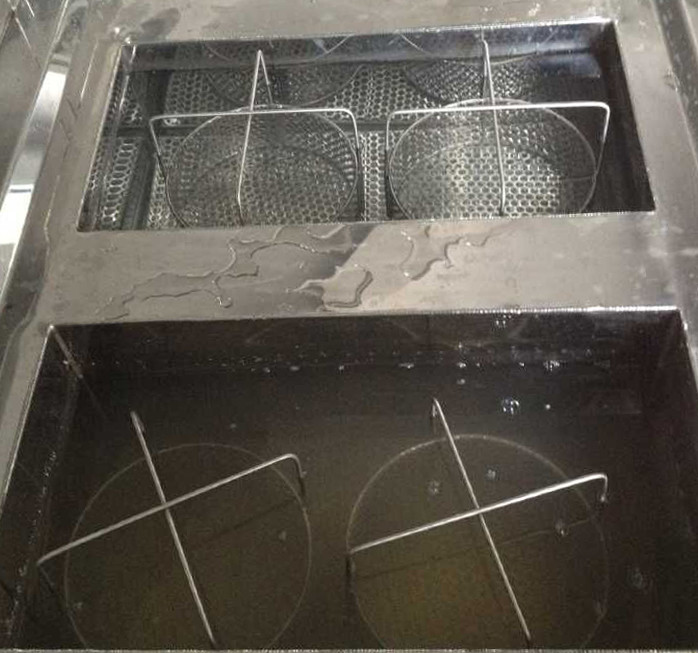

Step 1: Cleaning:

The first stainless steel tank is used for ultrasonic cleaning, and includes the components required to remove contaminants from part surfaces. For the best results and for most applications, we recommend our patented multiple frequency ultrasonic system.

A high-efficiency heater is used to heat the ultrasonic cleaning tank which features a digital temperature controller so that bath temperature is continuously displayed.

Particles and contaminants are automatically removed by means of AGSONIC's particulate filtration system – thus helping to increase the longevity of the cleaning agent. Filters are conveniently housed for easy removal and servicing. Surface skimming options are also available to prevent re-deposition of contaminants back onto parts when removed from the tanks.

Finally, the ultrasonic cleaning cycle is switched off when complete by means of the digital ultrasonic timer which comes as a standard feature of both MTC-4 systems, or by the included optional Automation Systems.

Steps 2 and 3: Rinsing and/or rust prevention:

Most commonly, the second and third stainless steel tanks are used for primary and secondary submersion rinsing operations.

In this configuration, the system can provide zero-residue cleaning results when the second rinse tank is supplied with purified or deionized water. In rinse/rinse configurations, tanks are designed in Reverse Cascade Overflow Format which greatly reduces the consumption of water since both rinse tanks share the same water supply.

In clean/rinse/rust dip/dry systems the second tank can be manufactured for use as a dipping bath for immersing parts in rust preventative fluids to prevent corrosion of such parts.

Step 4: Drying:

The fourth tank features a partially-recirculating, high volume drying system. This includes a core electric heater and blower that direct hot air straight to the cleaned parts, thus maximizing drying speed. Parts are dried more by air volume than by excessive heat which means that operators can handle parts baskets soon after completion of the drying process, without the need for a lengthy cooling period. The system also includes a 4" gated exhaust to channel moist air out of the drying tank and a stainless steel cover to keep the drying environment contained. A specifically designed air duct system prevents liquids from entering into the system.

System Design Features:

- Two standard configurations; Clean/Rinse/Rinse/Dry or Clean/Rinse/Rust Dip/Dry.

- Internally mounted components for cleaner exterior appearance.

- Easily accessible components facilitate maintenance operations.

Transducers are constructed of heavy gauge 304 / 316 L stainless steel. The radiating surface is hard chrome plated to reduce surface erosion.

All internal wiring uses high temperature Teflon insulated multi strand wire. Interconnecting wiring, the electrostrictive element electrodes and all connections are vibration dampened to prevent failure from vibration fatigue

Each Transducer is made custom to fit your application.

The Advantages of AG Auto part ultrasonic cleaning machine

Ultrasonic cleaning machine delivers high performance industrial strength, cleaning action on Engine block, carburetor and Engine parts

01: Cleans carbon deposits from carburetors and all manner of engine parts

02: Removes stubborn oil grease, lubricants, paint, rust, and dirty (with-pre-cleaning in same cases

03: Aluminum sate

04: Penetrates deep into the part and cleans holes, small apertures and crevices

05: Clean sensitive parts like wiring and plastic without damage

06: Does not require line-of-sight for effective cleaning

07: Ensures part longevity due to high degree of cleanliness

Ultrasonic Cleaning tank models for your choice:

| Model |

Tank size |

Unit size |

Volume |

Ultrasonic power |

Frequency |

Heating power |

Timer |

Heating temperature |

| LxWxH(mm) |

LxWxH(mm) |

(L) |

(W) |

(kHz) |

(KW) |

(MIN) |

(℃) |

| T-12S |

500x300x250 |

640x440x470 |

38 |

600 |

28/40 |

1.5 |

1-99 |

0-80

|

| T-18S |

500x350x350 |

640x490x570 |

61 |

900 |

1.5 |

| T-24S |

550x400x400 |

690x540x620 |

88 |

1200 |

3 |

| T-30S |

600x450x400 |

740x590x620 |

108 |

1500 |

3 |

| T-36S |

600x500x450 |

740x640x670 |

135 |

1800 |

4.5 |

| T-48S |

700x500x500 |

840x640x720 |

175 |

2400 |

6 |

| T-60S |

800x600x550 |

940x740x770 |

264 |

3000 |

7.5 |

| T-72S |

1000x600x600 |

1140x740x820 |

360 |

3600 |

9 |

Engine Parts Cleaning, Car Engine Parts Cleaning, Truck EngineParts Cleaning, Motor Bike Engine Parts Cleaning.

The Engine Parts division specialises in the Ultrasonic Cleaning of Engine Parts, Car engine parts, Truck engine parts and Motor bike engine parts to both trade customers and individuals throughout the world

Our Ultrasonic cleaning process, can effectively clean the following components- Aluminum castings, engine blocks, Carburetors, Cylinder Heads, Engines, Engine Components, Gear Boxes, Filters, Tubes and Valves.

Benefits of immersible ultrasonics :

- Cleans delicate parts without damage

- Cleans cracks and crevices that would be difficult to reach with the hand

- Does not require line-of-sight for effective cleaning

- Doesn’t use harsh chemical solvents that are dangerous for workers and the environment

- Safe for aluminum, magnesium and zinc

- Biodegradable cleaner

- Clean multiple pieces at once without having to brush by hand – saves time and money

Ultrasonic Engine Cleaning remove oil , dirty ,Perfect cleaning effect !

Why choose ultrasonic cleaning machine to clean our engine block and engine parts?

Clean intricate and difficult to reach areas easily

A major challenge of any cleaning system is the difficulty faced in tackling tiny spaces, intricate geometries, and difficult to reach surfaces, ultrasonic cleaning penetrates even blind holes and small apertures, that previously had hit-and miss success rates, the uniform agitation of the cleaning solution ensures that the cleaning action penetrates even hard to reach areas that previously required specialized brushes and other complicated cleaning devices with no real guarantee of a successful and consistent cleaning outcome, various factors go into determining which combination of an ultrasonic unit and chemical solution is suited to your particular requirement

For effective cleaning the ultrasonic cleaning machine must use the right of cleaning chemistry, operate at the right temperature and use the correct frequency, the part to be cleaned the contaminant to be removed and the degree of soil, determine this, our years of experience advising manufacturing and maintenance clients on the right process for their cleaning needs help us identify the exact product combo that you need, just send AG SONIC email or call us, and we’ll guide you to the right solution quickly

FAQ:

Q - Will sonics in a rinse tank w/o soap continue to remove embedded debris?

Absolutely. While detergents aid in the formation of the bubble, cavitation is still very effective in plain water or demineralized water. Where there is cavitation there can still be cleaning.

Q - Are there rules for racking parts- material, coating, or part orientation?

Yes. Never put the parts on the bottom of an ultrasonic tank. You will prevent the correct movement of the diaphragm and interfere with the creation of ultrasonic energy. You can also subject the parts to damage. Parts should be racked in a basket or work holder designed to handle your specific part. This is very important in high end cleaning systems where you want the cleanest part possible. You should always use a stainless steel basket, as softer materials will absorb the ultrasonic energy. Never use plastic or other soft materials. If your part is easily damaged or scratched, stainless steel racks with Nylobond or Teflon coatings are available. Parts should be arranged in a single layer, this gives the cleaning fluid an opportunity to circulate and remove particulate from the immediate area of the part. When removing the parts from the cleaning solution a single layer prevents the upper parts from shedding particles on the lower parts. Never put the parts on the bottom of an ultrasonic tank. This is like putting your thumb on a speaker diaphragm in a radio. You will prevent the correct movement of the diaphragm [bottom or side of the tank] and interfere with the creation of ultrasonic energy.

Q - Does the material or shape of the sonic tank impact their effectiveness?

Tank materials play a large part in the absorption and dispersion of ultrasonics. As mentioned previously soft materials such as plastics will absorb the ultrasonics. They can however be used if the ultrasonic power is boosted to overcome the absorption. Tanks shape plays less of a part in design but needs to be considered. Ultrasonic power does reflect from not only tank walls but also from the water surface.

Engine cylinder Head Cleaning Effect:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!