Plastic Welder For n95 Face Welding Equipment With Generator Transducer Horn

The generator adopts new technology, full digital, longer service life, easy to operate, automatic, frequency tracing.

AG Sonic Ultrasonic Welding machine Application

Nonwoven Machinery, Nonwoven Bag Making Machine, Nonwoven Surgical Cap Making Machine, Nonwoven Bouffant Cap Making Machine, Nonwoven Shoe Cover Making Machine, Nonwoven Ultrasonic Plastic Welding Machine, Ultrasonic Lace machine, Three Layers Bag Making Machines, Plastic Bag Making Machine, Stationery, Machinery, Automation Equipment, etc.

Ultrasonic welding principle:

Hand-held ultrasonic welding machine, several commonly available operating frequency, 20KHz, The principle is the use of sound waves reached the peak position of the gap between the plastic, in the case of pressure, so that the two fusible elements which could be part of the plastic parts in contact with each other to produce the high-speed friction melts, the contact surface of the plastic fusion, achieve the purpose of processing.

Machine Features:

1. Hand-held design, welding convenient, compact machine design, small size does not occupy space.

2. Frequency: 20KHz.

3. Slight noise, work environmental, no pollution.

4. Welding fast, each welding time 0.01-9.99 seconds.

5. High welding quality, fine welding results.

Applications:

1. Suitable for spot welding products Φ1-15mm.

2. Suitable for riveting, welding, dots, folder location.

3. For the SD card, U disk, mobile phone antennas, headsets and other communications products, and microelectronics.

20khz Digital Control Ultrasonic Ear Loop Welding Machine

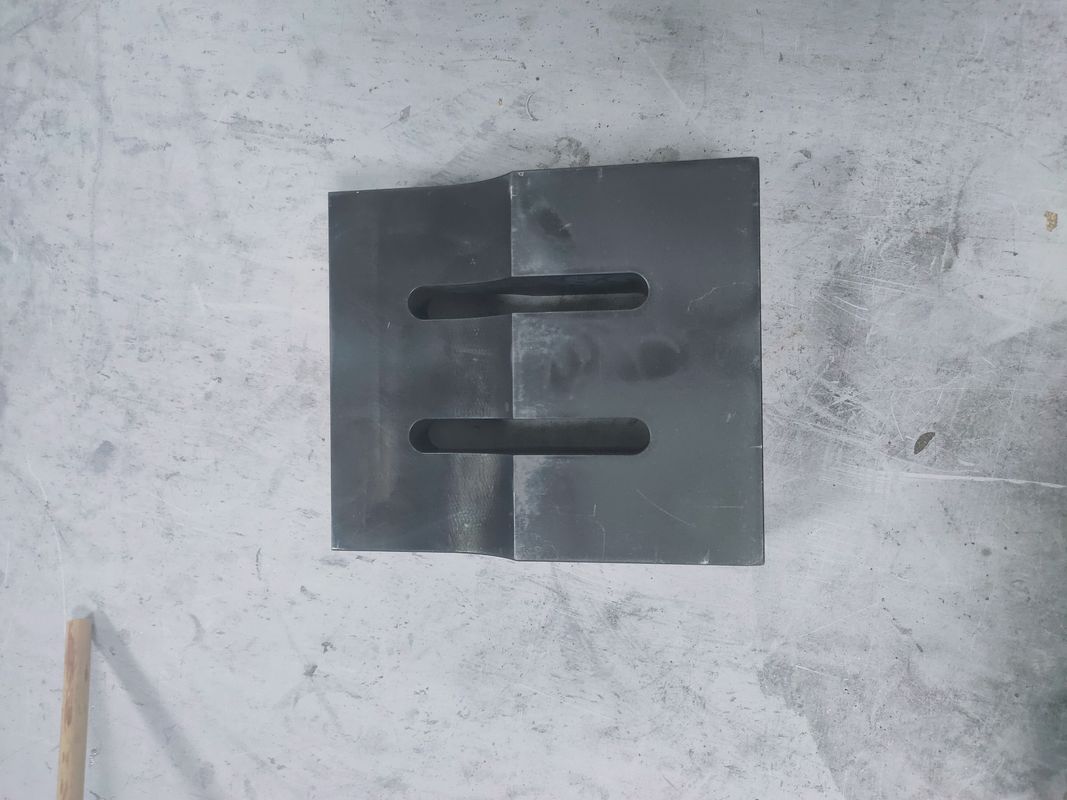

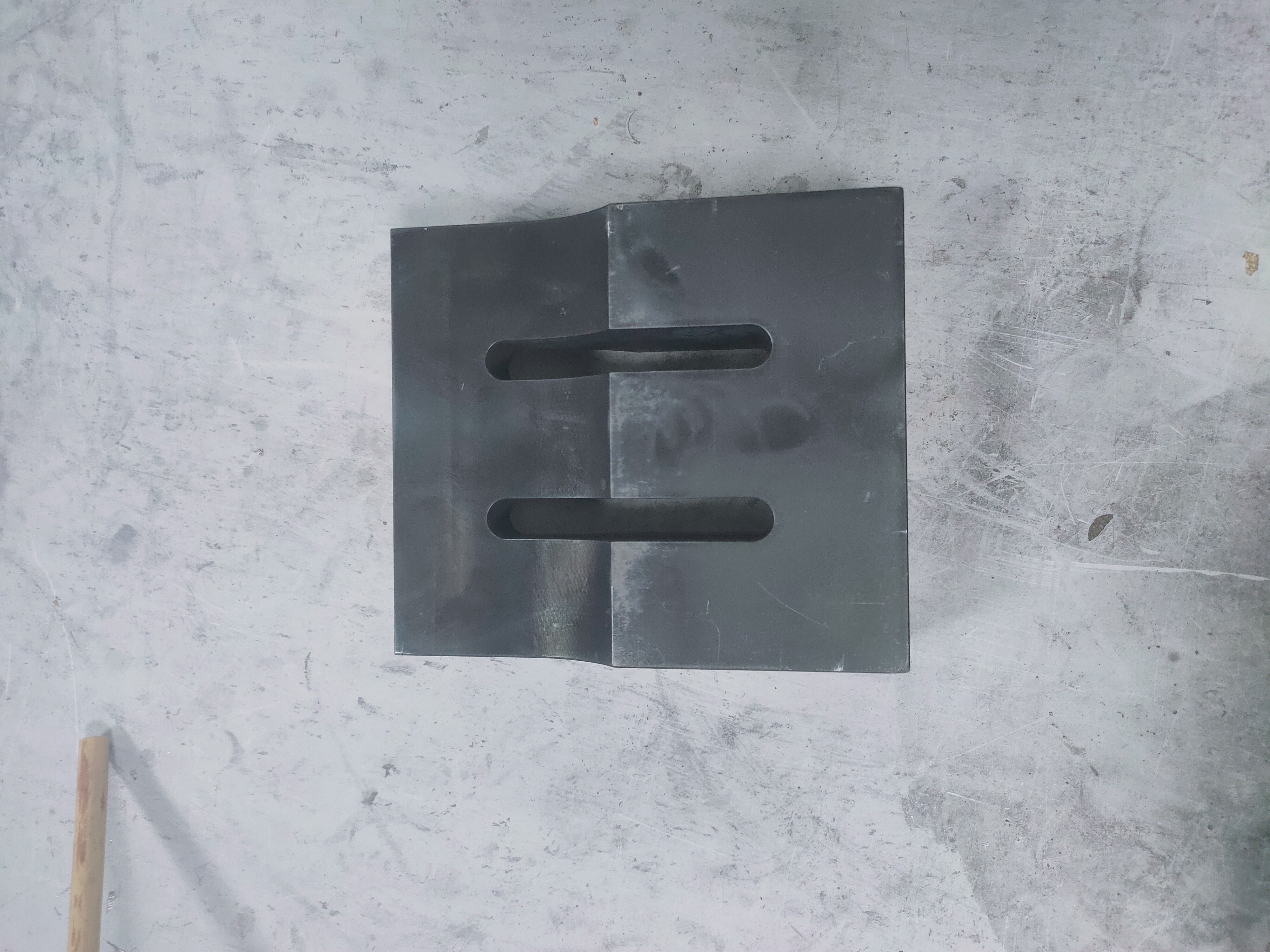

Ultrasonic transducer is the core device that converts electrical energy into mechanical energy (ultrasonic), the piezoelectric ceramic chip is selected from well-known supplier, and can give a strong and stable output. The frequency is mainly 20kHz, 15KHZ ,we can provide ultrasonic transducer, ultrasonic transducer with booster, ultrasonic transducer with booster and sonotrode separately as your request.

How Ultrasonic Welding work:

high-frequency vibrations are applied to two parts or layers of material by a vibrating tool, commonly called a “horn or sonotrode.” Welding occurs as the result of heat generated at the interface between the parts or surfaces.

Powerful and steady output

Hand booster, flexible to use

Easy maintenance, easy to carry

Ideal for 1-15mm welding point

The machine is made of quality components.

Features:

1. Ultrasonic system is divided into three parts, ultrasonic generator, ultrasonic transducer and ultrasonic die, with the three parts is a complete ultrasound system.

2. The ultrasonic generator is also a part of the ultrasonic energy production, our ultrasonic generator adopts imported electronic components, hardcover.

3. With a high-powered ultrasonic transducer with a titanium alloy ultrasonic die head.

4. The machine failure rate is low, consumables, durable, easy installation and debugging, maintenance is simple.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!