industrial ultrasonic cleaner for auto parts carburetor fuel injectors degreasing

industrial ultrasonic cleaner Advantages:

* With separate generator control to avoid water leakage and electric leakage.

* With 5V safe control panel to avoid electric shock.

* Reduced unit size to save the cost.

Why choose ultrasonic cleaning?

Ultrasonic cleaning is a process that uses ultrasound (usually from 20–400 kHz) and an appropriate cleaning solvent (sometimes ordinary tap water) to clean items. The ultrasound can be used with just water, but use of a solvent appropriate for the item to be cleaned and the type of soiling present enhances the effect. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on the object to be cleaned.

Ultrasonic cleaners are used to clean many different types of objects, including jewelry, lenses and other optical parts, watches, dental and surgical instruments, tools, coins, fountain pens, golf clubs, fishing reels, window blinds, firearms, car fuel injectors, musical instruments, gramophone records, industrial parts and electronic equipment. They are used in many jewelry workshops, watchmakers' establishments, and electronic repair workshops.

Why Clean Tools Heads, Injectors And Injection Pumps Engine with Ultrasonics?

Delivering and using clean parts is not always obvious. Certainly, no one wants to handle a dirty part or install it into a critical machine, but dirt, debris and contaminants can cause problems for manufacturers and end users. From the merely frustrating to catastrophic, dirty parts can cause critical components to exceed tolerances and even fail damaging valuable equipment and property while contamination (everything from grease, oil and chemicals to viruses and bacteria) can seriously harm users.

Ultrasonic Cleaning tank models for your choice:

| Model |

Tank size |

Unit size |

Volume |

Ultrasonic power |

Frequency |

Heating power |

Timer |

Heating temperature |

| LxWxH(mm) |

LxWxH(mm) |

(L) |

(W) |

(kHz) |

(KW) |

(MIN) |

(℃) |

| T-12S |

500x300x250 |

640x440x470 |

38 |

600 |

28/40 |

1.5 |

1-99 |

0-80

|

| T-18S |

500x350x350 |

640x490x570 |

61 |

900 |

1.5 |

| T-24S |

550x400x400 |

690x540x620 |

88 |

1200 |

3 |

| T-30S |

600x450x400 |

740x590x620 |

108 |

1500 |

3 |

| T-36S |

600x500x450 |

740x640x670 |

135 |

1800 |

4.5 |

| T-48S |

700x500x500 |

840x640x720 |

175 |

2400 |

6 |

| T-60S |

800x600x550 |

940x740x770 |

264 |

3000 |

7.5 |

| T-72S |

1000x600x600 |

1140x740x820 |

360 |

3600 |

9 |

Ultrasonic Machines Feature :

1) Tank materail is SUS304 with 2mm thickness, Human hand argon welded, Sturdy and durable resistance to high tempearture

2) 50W industrial transducers, outstanding cleaning effects

3) External ultrasonic generator

4) Power adjustable, choose different power according to different cleaning objects

5) Digital timer: 1~99hours timer adjustable. continious working for long time.

6) With memory function, no need to reset time and temperature every time.

7) 20~80C adjustable, 9KW heating panel, faster cleaning

8) Industry use power cord, more safer.

9) Can bear 50~100KG cleaning objects

10) Accessories: Machine with stainless steel basket, drainage, lid, movable castors.

The reason ultrasonic cleaning device is one of the best tools For Engine Cylinder Heads Alloy Wheels

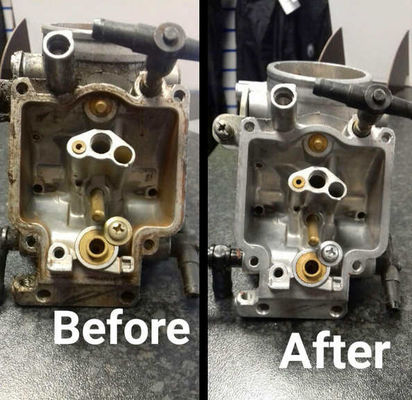

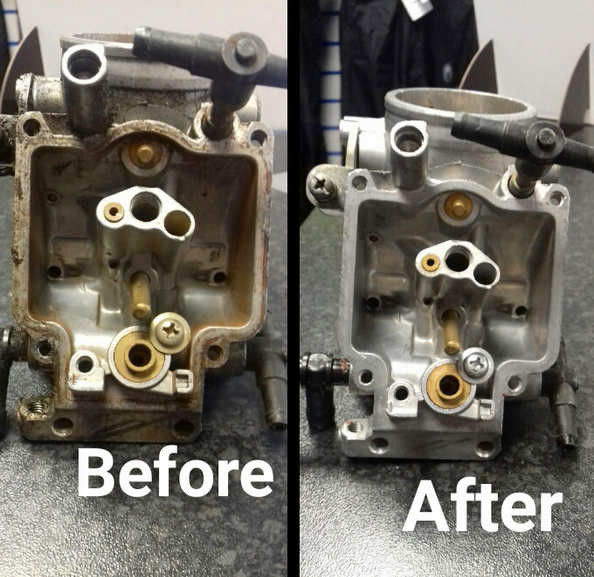

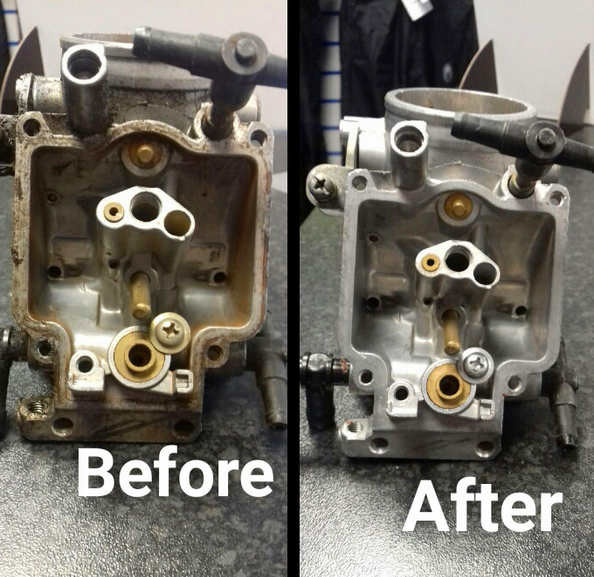

Small needle valves, jets, orifices, and ports of a carburetor; intake and exhaust ports or a cylinder head; pistons; injector nozzle; ring; pinion gears and much more can be cleaned and made just like brand new within few minutes.

Removing the accumulated oil sludge, varnish and carbon deposits, from these engine parts, manually by hand can be a tedious and long process. But using an ultrasonic parts cleaner makes all this a breeze. And for this reason ultrasonic cleaning device is considered one of the best tools in the auto mechanic’s garage. Get one now if you haven’t tried it yet!

Why choose ultrasonic cleaning machine to clean our engine block and engine parts?

For effective cleaning the ultrasonic cleaning machine must use the right of cleaning chemistry, operate at the right temperature and use the correct frequency, the part to be cleaned the contaminant to be removed and the degree of soil, determine this, our years of experience advising manufacturing and maintenance clients on the right process for their cleaning needs help us identify the exact product combo that you need, just send AG SONIC email or call us, and we’ll guide you to the right solution quickly

FAQ:

Q:What are the advantages of AGsonic ultrasonic cleaner over traditional cleaning methods?

A:1.minimize the use of manual labor

· 2.make cleaning and degreasing without the use of organic solvents

· 3.clean hard to reach areas of products and remove all types of dirt

·4.shorten the processes such as extraction, dispersion, purification, chemical reactions

·5. eliminates costly mechanical and chemical cleaning of heat exchangers

Ultrasonic Tank Cleaners For Automotive Parts Cylinder Heads Fuel Injections Cooler Plates

Engine cylinder Head Cleaning Effect:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!