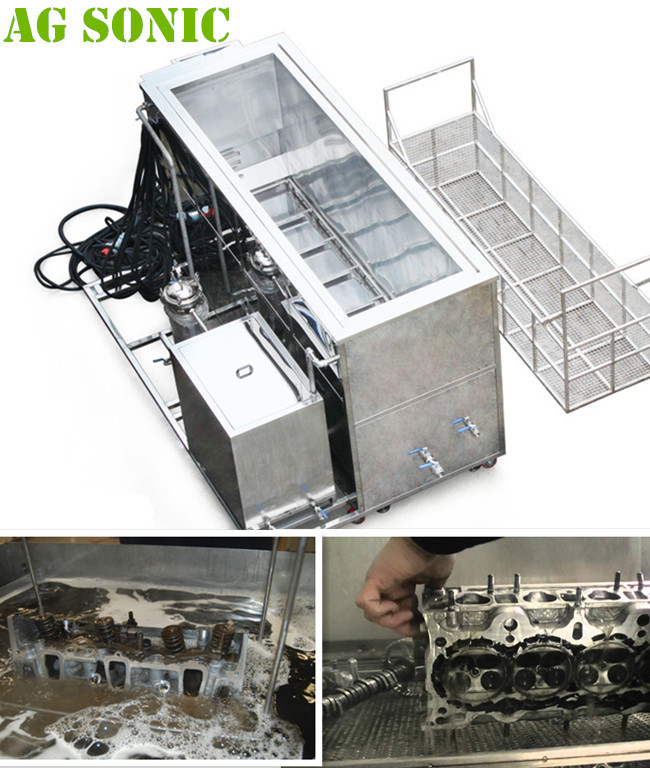

Garage Engine Ultrasonic Cleaning System With Closed Filtration System To Minimize The Consumption Of Washing Liquid

Why Use Cylinder Head Engine Block Cleaning ?

Agsonics is renowned for their professional cleaning service to the motor industry.

How does ultrasonic cleaner technology clean?

Cavitation bubbles are vacuum cavities as tiny as red blood cells, or about 8 thousandths of a millimeter across. They are so small that it would take 1,250 of them lined up in a row to reach 1 cm long.

Under pressure of continuous vibration, these bubbles stretch and compress at a fast rate. Once they reach a certain size, as determined by the frequency and strength of the sound waves produced, the bubbles lose structural integrity and collapse violently. When these implosions happen near a surface, the bubbles emit high-powered streams of plasma that travel at more than 500 miles per hour and collide with, agitate and remove even very tiny particles and substances from that surface.

AG Engine block ultrasonic cleaning machine

Suitable for all types of engine parts

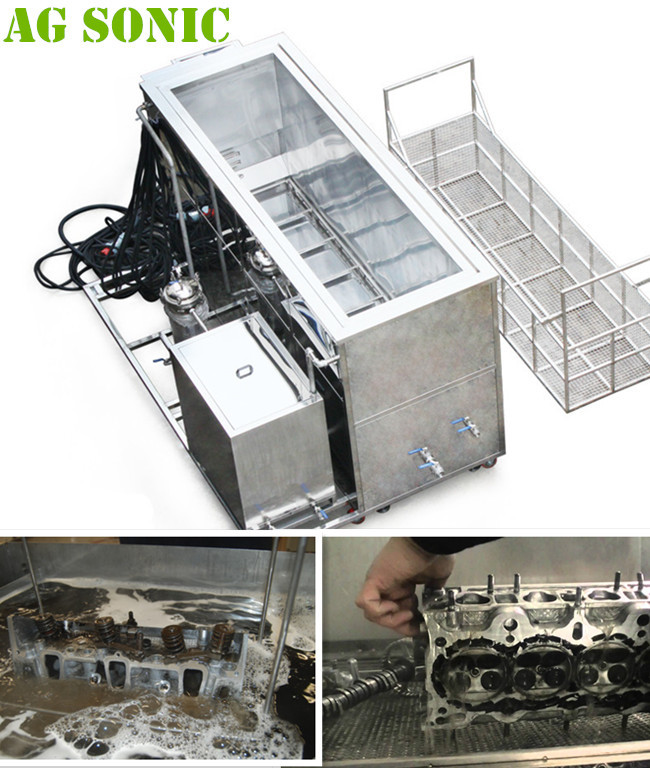

AG engine block ultrasonic cleaning machine effectively and thoroughly clean all types of engine parts

01: Automotive: thoroughly removes carbon deposits, grease, and other types of dirty and contaminants from carburetor, exhaust manifolds, cylinder blocks, 2-stroke and 4 stroke motorcycle engines, snow machines, ATV cylinders and heads, and more.

02: Marine: Suitable for inboard and outboard motors, the cleaning chemistry is both thorough and gentle on the aluminum parts reducing the risk of future corrosion

03: Aircraft: The high performance demands of aircraft engines establish the need for an intensive cleaning process that will restore the engine part to near original condition, our engine block ultrasonic cleaning machine easily, thoroughly, and safely clean both large and small parts, turbine blades, fuel nozzles, generator components, brakes and other parts that require periodic cleaning are all effectively and thoroughly cleaned using the ultrasonic cleaning process

Auto Parts Cleaning machine

We are manufacturing and supplying of Automotive Ultrasonic Cleaners. We offer a wide range of ultrasonic cleaners. These are Single or Multistage Ultrasonic Cleaners, which are both manually operated & fully automated systems. Further, the machine is widely used and appreciated by our clients due to its professional dependability and user friendliness.

Ultrasonic Cleaning system Design:

Considerations in the design of any cleaning system include the contaminants on the part(s), the required cleanliness level, the geometry and material of the part(s), the quantity to be processed, and the previous system design and layout (if applicable). The part geometry, production rate, and cleaning time required will determine the size of the cleaning system, once the overall process has been decided

Cylinder Heads And Engine Blocks Ultrasonic Cleaners

Automotive Ultrasonic Cleaners is primarily an aqueous tank systemthat uses ultrasonic energy to remove dirt, grease, oiland baked-on carbon from parts. Contaminants such aspaint, rust, glued-on gaskets, and heavy layers of bake don carbon can also be removed by ultrasonic cleaning but require more aggressive chemistries. Unlike someother cleaning processes, ultrasonic cleaning will notdamage intricate, lightweight, or easily damaged parts.

All ultrasonic baths are supplied complete with lid and basket

Product Description

Welcome to Cylinder Heads And Engine Blocks Cleaning, Truck Engine Parts Cleaning,

Our Ultrasonic cleaning process, can effectively clean the following components- Cylinder Heads And Engine Blocks And Aircraft Parts ,Aluminum castings, engine blocks, Carburetors, Cylinder Heads, Engines, Engine Components, Gear Boxes, Filters, Tubes and Valves.

AG Cylinder Heads And Engine Blocks ultrasonic cleaning machine are revolutionizing cleaning methods and processes on the Valve Plates , our Valve Plates And Aircraft Parts ultrasonic cleaning machine can clean all kinds of automotive, aircraft, and marine engine parts, ultrasonic technology for cleaning parts eliminates manual labor while providing you with superior cleaning action, most parts can be cleaned with environmentally friendly water-based solutions

Ultrasonic cleaning machines work on the principle of agitating cleaning solvents using high frequency sound waves, the ultrasonic agitation creates millions of microscopic bubbles that implode releasing vast quantities of energy, this action, know as cavitations, dislodges any contaminant stuck to the surface of a part, ultrasonic cavitations thoroughly cleans every surface in contact with the cleaning fluid

ultrasonic tank models for your choice:

ultrasonic tank models

|

Model

|

T-1144S

|

|

Interior tank size:

|

1200x1000x800 mm

|

|

Capacity:

|

960liters;

|

|

Material:

|

Stainless steel 304

|

|

Ultrasonic frequency:

|

28khz

|

|

Transducers;

|

With144 pieces transducers;

|

|

Ultrasonic power

|

7.2 KW

|

|

Generator power

|

220V, 50/60HZ

|

|

Working voltage:

|

380V 50HZ;

|

|

Warranty:

|

1 year.

|

Advantages of bath care systems

Dirt particle separator

for a prolonged service period of cleaning baths

Increased ultrasonic cleaning power

Stable bath quality

Cost reduction due to reduced waste water

quantities and low energy consumption

Suitable for various media

How the System Operates:

The system operates in the following manner:

- Parts are placed into the tank using the included stainless steel basket or other holding fixture.

- Once submerged, the START button is pressed, and the cover is closed. The ultrasonic system turns on, and the filter system turns off automatically. Parts are cleaned with the CROSSFIRE ultrasonic system at this time.

- The system will automatically turn off upon completion of the cycle.

- Operators can then return when the parts are clean.

The cover is opened and the batch of parts is placed onto the basket rest. Dripping liquids are directed back to the ultrasonic cleaning tank

RFQ:

How DOES ULTRASONIC WORK?

The Ultrasonic system employs a unique combination of ultrasonic and cleaning liquids . The soiled components are submerged in a bath. “Transducers” produce high frequency sound waves, which cause very small bubbles or “vacuum spaces”. When these “spaces” implode, the liquid impacts on the surface of all objects being cleaned with very high power, even in extremely inaccessible areas. This is the big difference between ultrasonic and other cleaning methods, with the additional advantage of cost-effective results.

Designing an Ultrasonic Cleaning Process

As with any type of equipment, ultrasonic cleaning systems should be matched as closely as possible to the job requirement. Labs and production areas with lower throughputs may choose a single ultrasonic tank followed by a sink rinse. Single tanks typically start at less than one gallon and up. Higher production areas may consider a manual or automated multiple station line in which one or more ultrasonic cleaning stations are followed by one or more rinses and an optional dryer.

Heavily contaminated parts may benefit from cleaning in more than one cleaning station. The first clean can remove gross contamination and the second completes the job. Ultrasonics may or may not be indicated in both stations depending on the type and level of contamination. For example in a scenario with heavy oil loading, a pre-clean might involve ultrasonic cleaning with surface skim to a coalescer to handle the oil. Once the heavy oil is removed in the first station, the ultrasonics in the second clean will be cavitating more directly with the part substrate to perform finer cleaning.

An ultrasonic tank work area should allow for at least two inches of clearance on all sides of the work load.

Small ultrasonic tanks are typically equipped with electric strip heaters, and the ultrasonic transducers are epoxy-bonded or vacuum brazed to a diaphragm usually located in the bottom of the tank.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!