Long Cable Ultra Sonic Bath Ultrasonic Probes Alone To Clean Long Cables Through The Big Bath

ULTRASONIC TECHNOLOGY

Ultrasonic technology has been used for many years in the

cleaning industry. Unimarine pioneered the use of ultrasonic technology to clean heavily contaminated equipment, such as heavy fuel oil-filters and heat exchangers. This required developing special chemicals and processes for each application.

With many years of experience Unimarine has the expertise to provide plant operators with simple, effective and fast cleaning systems. Depots worldwide are equipped with the ultrasonic cleaning systems providing continual research and development in the field of ultrasonic and chemical technology.

How DOES ULTRASONIC WORK?

The Ultrasonic system employs a unique combination of ultrasonic and cleaning liquids . The soiled components are submerged in a bath. “Transducers” produce high frequency sound waves, which cause very small bubbles or “vacuum spaces”. When these “spaces” implode, the liquid impacts on the surface of all objects being cleaned with very high power, even in extremely inaccessible areas. This is the big difference between ultrasonic and other cleaning methods, with the additional advantage of cost-effective results.

THE EQUIPMENT

The latest Technology has been incorporated in our equipment to provide reliability, flexibility and ease of operation. Backed

APPLICATIONS

The cleaning of heavily contaminated fuel and lubricating oil filters, cylinder heads and air coolers is often difficult. The use of only a cleaning agent is generally unsatisfactory, as only a part of the residues will be removed. In most cases carbon residues and other solid materials will be left behind. In these cases the use of ultrasonic sound waves in combination with a special cleaning agent gives good results. The special detergents in the cleaning agent keep the contamination dispersed in the liquid and the complexing agents will partly dissolve them.

ULTRASONIC CLEANER has been specially developed for use in ultrasonic baths for the cleaning of all materials except zinc, galvanized parts and / or magnesium alloys. We advice to test light-metal alloys (aluminum, magnesium etc.)

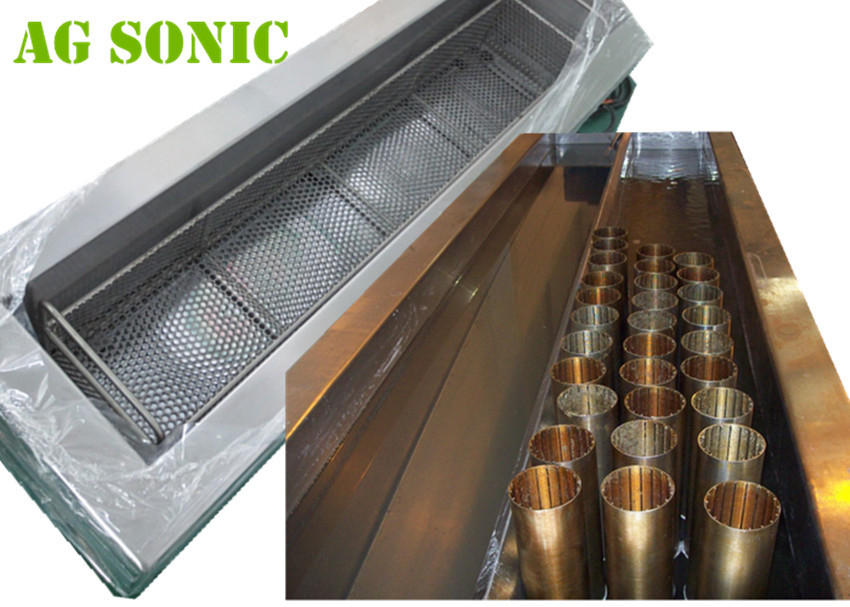

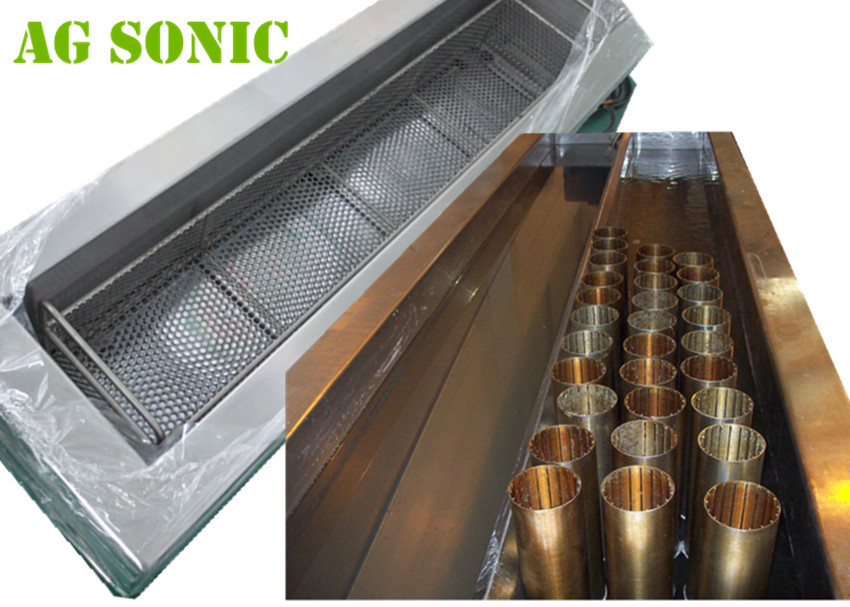

What Long Cable Ultra Sonic Bath can do ?

Ultrasonic cleaners remove dirt, oils, lubricants, carbon, rust,and other types of grime that build up on engines and mechanical parts. Grooves, internal passageways, seals, and other hard to reach areas are cleaned easily, eliminating hours of disassembling and reassembling complex parts. Carburetors, pistons, cylinder heads, aluminum parts, and brake calipers are a few examples of components that are cleaned thoroughly with no manual scrubbing in an ultrasonic cleaner

Basics and spcifictaion

| Model |

T-1144S |

| Interior tank size: |

1200x1000x800 mm |

| Capacity: |

960liters; |

| Material: |

Stainless steel 304 |

| Ultrasonic frequency: |

28khz |

| Transducers; |

With144 pieces transducers; |

| Ultrasonic power |

7.2 KW |

| Generator power |

220V, 50/60HZ |

| Working voltage: |

380V 50HZ; |

| Warranty: |

1 year. |

.

Ultrasonic Cleaning system Design:

Considerations in the design of any cleaning system include the contaminants on the part(s), the required cleanliness level, the geometry and material of the part(s), the quantity to be processed, and the previous system design and layout (if applicable). The part geometry, production rate, and cleaning time required will determine the size of the cleaning system, once the overall process has been decided

Cleanliness considerations :

In a typical aqueous ultrasonic cleaning system, it is the cleaning stage(s) that will remove or loosen the contaminants. The following rinse stage(s) remove any remaining loosened soils and residual detergent, and a dryer removes any remaining rinse water. The overall process of the system is usually determined experimentally. We have an applications lab where, through a process of experience, trial, and error, a properly designed cleaning process can be determined to meet the cleanliness levels specified. There are a variety of ways to check for cleanliness. Some are as simple as a water break test on the part to see if most oil has been removed. Others are as elaborate as surface quality monitoring that uses optically stimulated electron emission technology to measure thin films of contaminants down to the Angstrom level.

Ultrasonic Cleaning of Engine Parts, Car engine parts, Truck engine parts and Motor bike engine parts

Our Ultrasonic cleaning process, can effectively clean the following components- Aluminum castings, engine blocks, Carburetors, Cylinder Heads, Engines, Engine Components, Gear Boxes, Filters, Tubes and Valves.

Cylinder Heads And Engine Blocks Ultrasonic Cleaners

Automotive Ultrasonic Cleaners is primarily an aqueous tank systemthat uses ultrasonic energy to remove dirt, grease, oiland baked-on carbon from parts. Contaminants such aspaint, rust, glued-on gaskets, and heavy layers of bake don carbon can also be removed by ultrasonic cleaning but require more aggressive chemistries. Unlike someother cleaning processes, ultrasonic cleaning will notdamage intricate, lightweight, or easily damaged parts.

All ultrasonic baths are supplied complete with lid and basket

High Capacity Ultrasonic Cleaning Systems are designed for medium and heavy duty industrial applications. They are fully integrated, with an ultrasonic generator and cleaning tank in a single enclosure. A 10-gallon tank capacity is enough to handle large bulky parts or for batch cleaning of small components. High Capacity Ultrasonic Cleaning Systems' deep-drawn tank of 304L stainless steel has no corner welds or other dirt-catching surfaces.

How the System Operates:

The system operates in the following manner:

- Parts are placed into the tank using the included stainless steel basket or other holding fixture.

- Once submerged, the START button is pressed, and the cover is closed. The ultrasonic system turns on, and the filter system turns off automatically. Parts are cleaned with the CROSSFIRE ultrasonic system at this time.

- The system will automatically turn off upon completion of the cycle.

- Operators can then return when the parts are clean.

The cover is opened and the batch of parts is placed onto the basket rest. Dripping liquids are directed back to the ultrasonic cleaning tank

RFQ OF ULTRASONIC CLEANER :

why clean parts with ultrasonic?

Delivering and using clean parts is not always obvious, certainly, no one wants to handle a dirty parts or install it into a critical machine, but, dirty, debris and contaminants can cause problems for manufactures and end users, from the merely frustrating to catastrophic, dirty parts can cause critical components to exceed tolerances and even fail damaging valuable equipment and property while contamination (everything from grease, oil and chemicals to viruses and bacteria) can seriously harm users.

How to choose cleaning chemistry

Depending on the type of cleaning requirement and the substrate that needs cleaning a detergent solution or a similar aqueous medium can dramatically increase the cavitations, lowering the surface tension of the liquid reduces the energy required to form the bubbles and when combined with inherent cleaning property of the solution results in superior micro cleaning of the solid surface

The choose of the cleaning medium is critical, the nature of the substrate and contamination are the key factors in selecting the cleaning chemistry, which is typically aqueous or semi-aqueous

Buying guidance

Please provide AG SONIC below information to get recommendation

What type of object do you want to clean (Metal, plastic, machine parts, etc)?

What type of contamination do you want to remove from the object?

How large is the object and how many do you need to clean?

What is your time frame?

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!