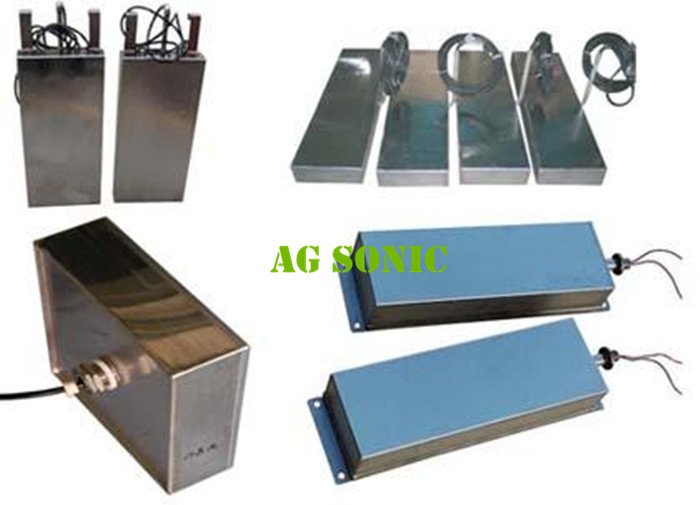

40kHz Immersible Ultrasonic Transducer Generator for Cleaning and Degreasing

The ultimate flexibility in ultrasonic design and service, custom built for you.

Features:

- Original BLT type transducer

- SUS stainless steel housing Hard-Cr plating Treatment ( 20 + microns )

- Adaptable for continuous operation

- Adjustable ultrasonic power

- With separate control ultrasonic electronic generator

- Custom made size is available

- Transducer no./transducer box: range[6pcs~40pcs per box]

- Ultrasonic power: range[300W~2000W]

- Ultrasonic frequency: 28KHZ/40KHz

Introduction:

AG Ultrasonics immersible transducers are constructed of cavitation resistant, bright annealed 304/316L stainless steel with robotically welded seams to ensure a long life.

You can design these customized submersible units into your new ultrasonic systems or retrofit them into existing systems to introduce ultrasonic precision cleaning. The cleaning load of your parts tank will determine the number and placement of the submersible transducers, which are available in custom sizes, wattage, and frequencies — including 25 kHz, 40 kHz, 58 kHz, 132 kHz, 192 kHz, 470 kHz, and 1000 kHz — as well as custom combinations including 20/40 kHz and 58/192 kHz. They can be mounted on either the sides or bottoms of the cleaning tanks, depending upon their geometry.

By using a AG modular submersible ultrasonic transducer, you ensure easy servicing, because each one can be easily replaced in minutes thanks to our flexible mounting schemes. You can also move our immersible transducers from tank to tank, or reposition them on tanks as required for special situations and needs. And you can rack-mount a series of AG immersibles so that they can be installed and/or removed as a group to speed up tank cleanings, inspections, and maintenance.

Call to learn more about our customized flexible, hand pipe, and bulkhead ultrasonic immersible transducers.

Specifications:

| Model |

Material |

Transducers |

Estimated volume |

Box size |

Cable

lead-out |

Ultrasonic frequency |

Ultrasonic power |

| (mm) |

(pcs) |

(L) |

(mm) |

|

(kHz) |

(W) |

| TZ-1003 |

SUS304/SUS316L |

3 |

15 |

250x150x100 |

Rigid tube/

Flexible tube |

28/40 |

150 |

| TZ-1006 |

6 |

30 |

305x250x100 |

300 |

| TZ-1012 |

12 |

60 |

355x250x100 |

600 |

| TZ-1018 |

18 |

90 |

406x305x100 |

900 |

| TZ-1024 |

24 |

120 |

500x355x100 |

1200 |

| TZ-1030 |

30 |

150 |

550x406x100 |

1500 |

| TZ-1036 |

36 |

180 |

500x460x100 |

1800 |

FAQ:

Q: What frequency is better for my parts?

A: Frequency is suggested based on pollutants in the objects.

28kHz frequency is stronger, better for car/motor/truck/vessel parts clean (remove oils, grease, pastes, etc. )

40kHz is better for pcb boards, electronic parts, etc.

Higher precision goods, higher frequency.

Q: Can ultrasonic cleaning damage parts?

A: Although the effect of thousands of implosions per second is very powerful, the cleaning process is safe.

No damage to your daily objects.

Q: What cleaning solution should I use?

A: A large variety of different formulas designed for specific applications. Proper selection is crucial for

acceptable cleaning activity and to prevent unwanted reactions with the workpiece.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!