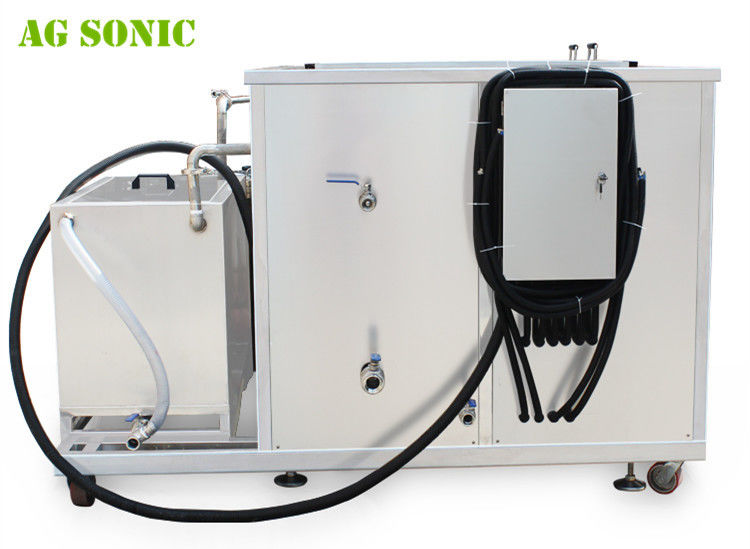

Electronic Ultrasonic Cleaning Equipment with Filtration to Recycle the Solvent

Ultrasonics: The ONLY Way to Clean with Confidence

Regardless of the source of the dirt or contamination, AG Ultrasonic Cleaning Systems are designed to accommodate a wide variety of uses in diverse industries. Fast, effective and efficient, our machines will allow you to clean virtually any type of part or component. The following is just a short list of the many different types of items that have been cleaned using our systems.

- Automotive (Car, Truck, Motorcycle) See Video Below

- Aviation (Helicopters, Aircraft and Ground Support)

- Personal Boat & Marine

- Injection Molds

- Restaurants, Bakeries & Kitchens (Oven Filters, Burners, Pots, Pans, Utensils)

- Machines of All Types

- Tools, Nuts, Bolts

- Extrusion and Deburring

- Almost anything made out of metal (ferrous and non-ferrous), plastic, vinyl, and wood.

- And much more

Features:

1. Whole machine made of SUS304 stainless steel, 2mm thickness tank for acid-proof, anti-corrosive.

2. Industrial grade ultrasonic transducer, moisture-proofed PCB.

3. Advanced generator, sweep frequency, high quality, better effect.

4. Ultrasonic power can be adjusted from 0-100%.

5. Temperature can be set from 30-110°C.

6. Industrial grade for 24 hours continuous working.

7. Ultrasonic frequency: 28kHz or 40kHz.

8. Fully portable, 36L and above volume machines are with wheels, locking wheels for stability.

9. With free lid and stainless steel SUS304 basket.

10. Customized according to customer’s request.

Specifications:

| Specifications for ultrasonic cleaner AG-720G |

| Model |

AG-720G |

| Special |

with filtration system |

| Tank capacity |

360L |

| Tank size |

1000x600x600mm |

| Unit size |

1140x740x820mm |

| Tank material |

2mm SUS304 |

| Ultrasonic power |

3600W |

| Heating power |

9KW |

| Timer |

1-99min adjustable |

| Heater |

0-80c adjustable |

| Frequency |

28/40khz |

| Control |

External generator, more stable |

| Optional |

pneumatic lift, rinsing tank, etc. |

| Voltage |

110V, 1phase; 220V, 3phases/220V, 1phase; 380V, 3phases |

| Warranty |

1 year |

| Packing |

1unit/wooden case |

FAQ:

Q: Why Clean Parts with Ultrasonics ?

A: Delivering and using clean parts is not always obvious. Certainly, no one wants to handle a dirty part or install it into a critical machine, but dirt, debris and contaminants can cause problems for manufacturers and end users. From the merely frustrating to catastrophic, dirty parts can cause critical components to exceed tolerances and even fail damaging valuable equipment and property while contamination (everything from grease, oil and chemicals to viruses and bacteria) can seriously harm users.

Q: Ultrasonic cleaning can offer:

A: Non-directional cleaning - clean where the sound and solution go

Reduced or eliminated need for disassembly

Consistent results - non-operator dependent

Non-contact cleaning - only the soil is removed, not the substrate

High efficiency - cleaning multiple parts at one time

Q: Advantages for Ultrasonic Parts Cleaning

A: here are many advantages to cleaning parts with Skymen Ultrasonic Cleaning Systems, not the least of which are our machine’s incredible versatility. In fact, our ‘unofficial’ motto is; If it can fit into water, you can clean it.

While the versatility is one major advantage allowing you to clean almost anything, there are several other advantages that will dramatically benefit both you and your clients/customers. These include:

- Clean Intricate Items with Ease: Ultrasonics easily reaches deep into even the most finely detailed surfaces.

- Cleans Fast: Many items can be cleaned in less than two minutes allowing you to quickly return them to your clients.

- Reduces Labor Costs: Fast cleaning means jobs can be completed in fewer hours.

- No Harsh/Dangerous Chemicals: Most items can be cleaned in just water with just a few ounces of our environmentally friendly cleaning solutions.

Filtration system to absorb the oil and recycle the solvent:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!