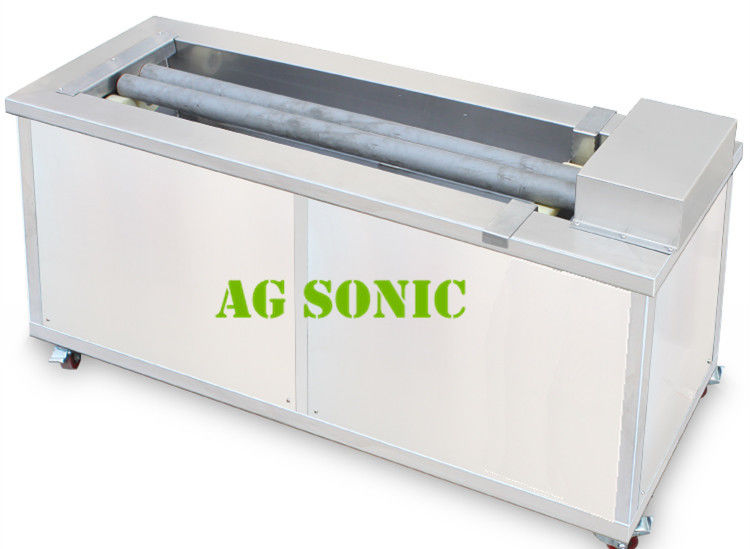

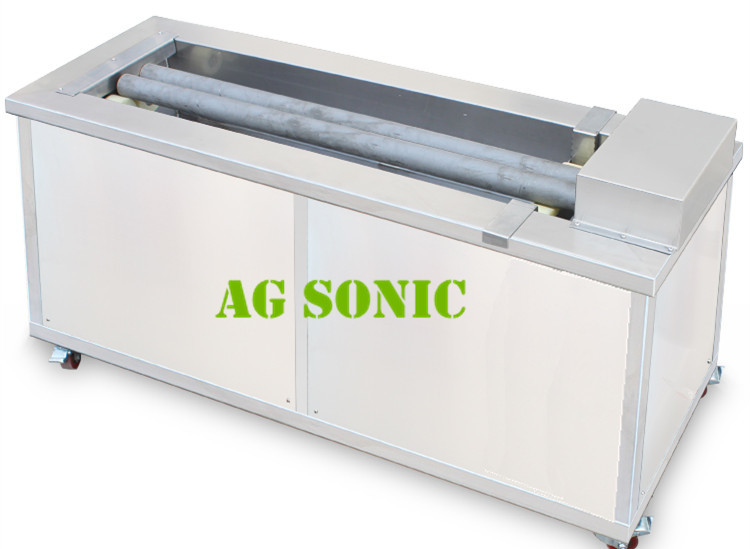

Printing Industry Ultrasonic Anilox Cleaning Machine for Round Parts SUS304

Main introduction of anilox roller ultrasonic cleaning machine:

After long time printing, Mesh blockage is likely to result in ink, paint, glue and other dirt coating, in this case, if the mesh cannot be cleaned thoroughly, the printing effect will be effected, printing cannot work normally, anilox roller ultrasonic cleaning machine can do perfect cleaning by ultrasonic cavitation, which can cause jetting force from tiny bubbles in exploding, the contamination will be removed totally, after several minutes cleaning, the anilox roller can come back to its origin, the ultrasonic intensity is visible under controlling, the anilox roller can spin in sitting the tank top, which can avoid axis of anilox roller immersion during cleaning, the spinning force also can fall off the dirty easily in driving, AG SONIC design rubber roller at two sides to drive the anilox roller in spinning as couples, which is separately controlled, is easier in operation, maintenance.

The cleaning method of anilox roller ultrasonic cleaning machine:

Coat the concentrated detergent on the surface of anilox roller according to the clogging degree

After several hours, put the anilox roller into the ultrasonic cleaning tank

At last, rinsing the anilox roller by cleaned water

Or put the detergent into the cleaning tank directly, its ratio depends on the clogging degree,

Ultrasonic have perfect cleaning effect, which can keep the anilox roller as clean as its new, AG SONIC can make to order, pls provide the diameter of your anilox roller and its anix. Also the max length of it to make a customized service

Features of anilox roller ultrasonic cleaning machine:

Cleaning rollers, anilox, ceramic anilox, metal anilox in various industries tank made of 2MM thick 316L stainless steel, resistant to acid, alkali corrosionMotor rotation system to drive the aniloxsuitable for ceramic anilox / metal anilox with overflow protection and water drain system Tank and shell made of quality stainless steel Professional testing, quality assurance Build-in timer, temperature controller and counter down buzzer high quality components, clear circuit

perfect to clean roller, anilox integrated design, easy maintenance Customized design and configuration are ok.

Wide application:

| Industry |

Cleaning objects |

| jewelry |

Jewelry, diamond, gold, silver products, |

| machinery |

Moulds, precision parts, pressing parts, camera parts, bearing, hardware

tools

|

| electronics |

PCB board, electronic parts, TV parts, computer parts |

| Auto industry |

engine parts, gear box, shock absorber, auto nozzle, cylinder, valve

|

| Dental& Medical |

dental tools, medical tools, injector, surgery tools, dropper, glass container |

| Plating& painting |

polishing parts, SUS cutter, tableware, plating |

| Food industry |

Oven tray, boiler, bottles, bottle cap, filters |

| Optical& watch maker |

optical lens, eyeglass, sunglass, metal, gold, jewelry, diamond, watch

band, watch cover, watch hand

|

| textile |

spinneret plate, rubber parts, plastic molds, toy |

|

others

|

seal, flapper, coins, pottery, bank card, IGBT |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!