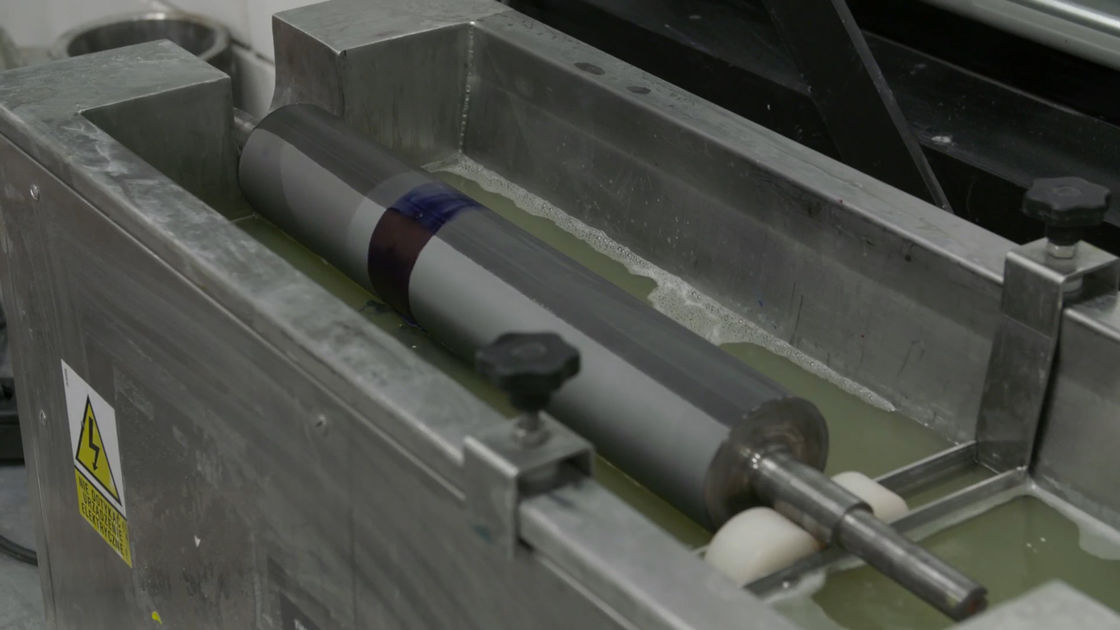

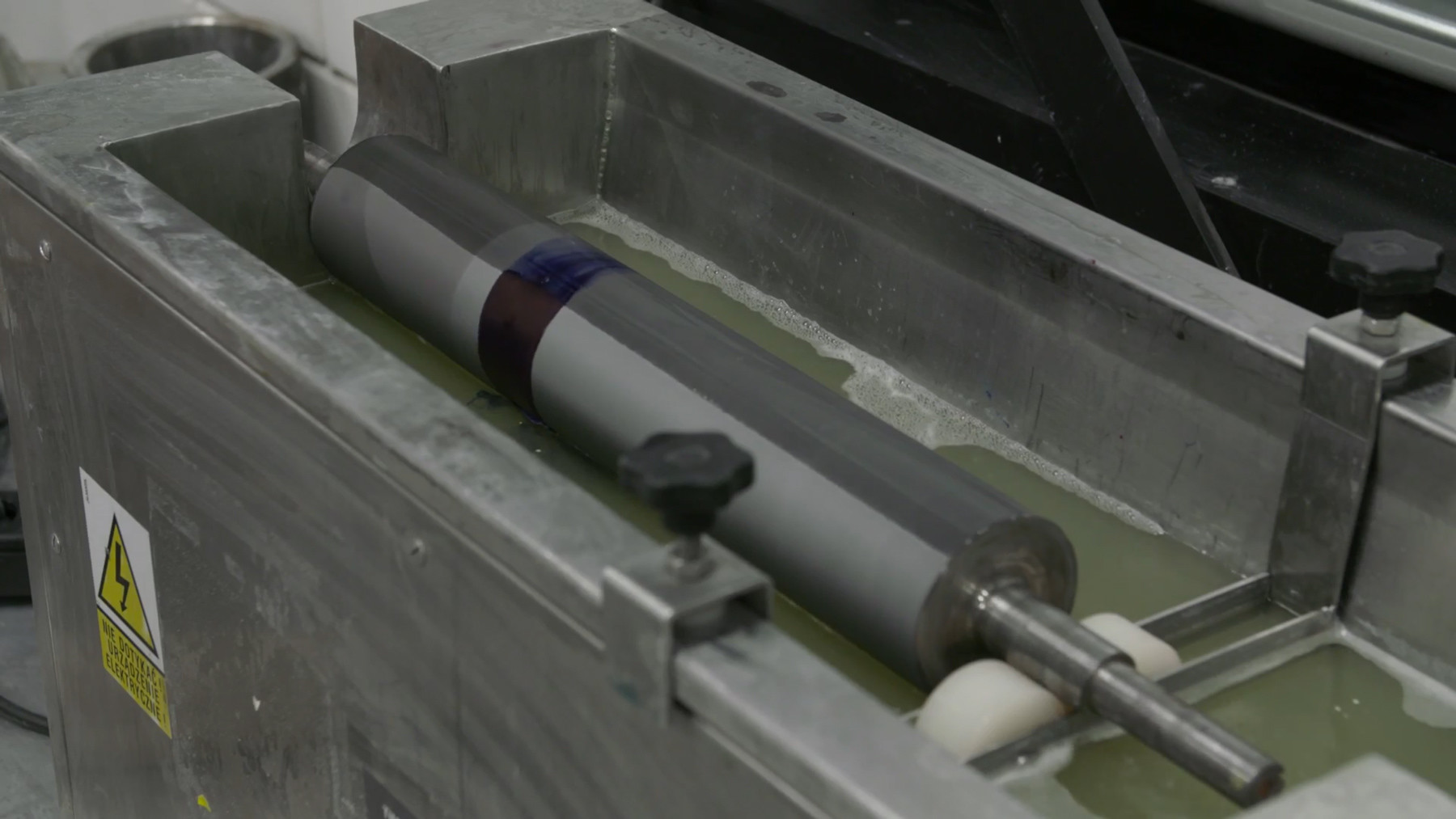

Ultrasonic Cleaning Commercial Printing Equipment with Ultrasonics and Rotating System

Cleaning Commercial Printing Equipment with Ultrasonics

Improve your printing production time and extend the life of your anilox rolls and sleeves with the regular use of ultrasonic cleaning.

Using ultrasonics is one of the only ways to clean the individual microscopic ink cells on rollers. To efficiently and effectively clean these and other printing parts, AG SONIC has developed methods that are able to be used with both aluminium and steel sleeves and rollers, as well as with all inks (including water-, solvent- and UV-based inks).

Ultrasonic cleaning saves money and minutes, resulting in faster production times. This cleaning method is effective at gently eliminating contaminants in the hard-to-reach spots of even the most intricate parts, extending their lives.

Features:

- Ultrasonic cleaning for cylinders is a modern and advanced cleaning technology. Its mechanism is the usage of a transducer to convert electrical signals into mechanical vibrations into the cleaning solution. When ultrasonic travels in liquids, cleaning fluid is compressed and expanded, and produce a few mechanical, mechanical force against a work, which will clean the printing rollers.

- As we all know, Anilox roll of flexo printing machine, laminating machine, offset printing machine Polish is part of the main. It directly depends on the quality of printing, laminating or varnishing. Because the roller parts not only plays a role of the ink roller, also plays an ink roller role, and even plays a role of rollers. It is used in the process, long pass from ink, ink or varnish which are more or less there are some impurities, these impurities after once inside the roller of a mesh, it will jam the ink roller, resulting in sharp decline in quality of printing or composite. In this case, you need to mesh with the ultrasonic cleaner the impurities earthquake, restores the ink roller effect. In addition, regular cleaning of Anilox roll will help better protect roller, extending the service life of the roller, plays the best print/composite effect.

Function and advantages:

- Choose water based with some additives used as cleaning agents,Low cost, excellent cleaning effect,the best and most affordable cleaning equipment;

- All imports of thick stainless steel acid, attractive and durable;

- Adjustable thermostatic system ;

- Split structure, easy to maintain, durable

- Washing machine tank with imported high quality stainless steel;

- Flat lid of the washing machine, the shell is made of high quality stainless steel.

Specifications:

| Item Name |

Powerful Anilox ultrasonic cleaner |

| Model |

T-36S |

| Ultrasonic Frequency |

40 Khz |

| Ultrasonic Power |

1800 W |

| Heating |

2400W |

| Tank Capacity |

185 L |

| Tank Dimension |

1650×450×250 mm |

| Tank Material |

2mm Thick 316L stainless steel |

| Shell Material |

stainless steel |

| Discharge drain |

have |

| Button controls |

Timer, Heating control, Motor control, Power switch |

| Product Dimension |

2050×550×600 mm |

OTHER MODELS AVAILABLE FOR REFERENCE

| Model |

T-06S |

T-12S |

T-18S |

T-24S |

| Ultrasonic Power |

300 W |

600 W |

900W |

1200W |

| Ultrasonic Frequency |

40Khz |

40 Khz |

40 Khz |

40 Khz |

| Heating Power |

400W |

800W |

1200W |

1200W |

| Tank Size(mm) |

360x175x120 |

800x320x100 |

1000x200x100 |

1200x320x150 |

| Tank Material |

316L stainless steel |

316L stainless steel |

316L stainless steel |

316L stainless steel |

| Shell Material |

stainless steel |

stainless steel |

stainless steel |

stainless steel |

| Power supply |

AC100V-120V,

AC220V-240V

|

AC100V-120V,

AC220V-240V

|

AC100V-120V,

AC220V-240V

|

AC100V-120V,

AC220V-240V

|

| Product Dimension(mm) |

400×220×360 |

840×520×680 |

1000×450×700 |

1520×370×700 |

| Model |

T-30S |

T-36S |

T-48S |

T-72S |

| Ultrasonic Power |

1500 W |

1800 W |

2400W |

3600W |

| Ultrasonic Frequency |

40Khz |

40 Khz |

40 Khz |

40 Khz |

| Heating Power |

1800W |

2400 W |

2400 W |

3000W |

| Tank Size(mm) |

1450×450×250 |

1650×450×250 |

2200×550×300 |

2500×550×300 |

| Tank Material |

316L stainless steel |

316L stainless steel |

316L stainless steel |

316L stainless steel |

| Shell Material |

stainless steel |

stainless steel |

stainless steel |

stainless steel |

| Power supply |

AC100V-120V,

AC220V-240V

|

AC100V-120V,

AC220V-240V

|

AC100V-120V,

AC220V-240V

|

AC100V-120V,

AC220V-240V

|

| Product Dimension(mm) |

1850×550×600 |

2050×550×600 |

2650×650×600 |

2900×650×600

|

Main introduction of anilox roller ultrasonic cleaning machine:

After long time printing, Mesh blockage is likely to result in ink, paint, glue and other dirt coating, in this case, if the mesh cannot be cleaned thoroughly, the printing effect will be effected, printing cannot work normally, anilox roller ultrasonic cleaning machine can do perfect cleaning by ultrasonic cavitation, which can cause jetting force from tiny bubbles in exploding, the contamination will be removed totally, after several minutes cleaning, the anilox roller can come back to its origin, the ultrasonic intensity is visible under controlling, the anilox roller can spin in sitting the tank top, which can avoid axis of anilox roller immersion during cleaning, the spinning force also can fall off the dirty easily in driving, AG SONIC design rubber roller at two sides to drive the anilox roller in spinning as couples, which is separately controlled, is easier in operation, maintenance.

The cleaning method of anilox roller ultrasonic cleaning machine:

Coat the concentrated detergent on the surface of anilox roller according to the clogging degree

After several hours, put the anilox roller into the ultrasonic cleaning tank

At last, rinsing the anilox roller by cleaned water

Or put the detergent into the cleaning tank directly, its ratio depends on the clogging degree,

Ultrasonic have perfect cleaning effect, which can keep the anilox roller as clean as its new, AG SONIC can make to order, pls provide the diameter of your anilox roller and its anix. Also the max length of it to make a customized service

Wide application:

| Industry |

Cleaning objects |

| jewelry |

Jewelry, diamond, gold, silver products, |

| machinery |

Moulds, precision parts, pressing parts, camera parts, bearing, hardware

tools

|

| electronics |

PCB board, electronic parts, TV parts, computer parts |

| Auto industry |

engine parts, gear box, shock absorber, auto nozzle, cylinder, valve

|

| Dental& Medical |

dental tools, medical tools, injector, surgery tools, dropper, glass container |

| Plating& painting |

polishing parts, SUS cutter, tableware, plating |

| Food industry |

Oven tray, boiler, bottles, bottle cap, filters |

| Optical& watch maker |

optical lens, eyeglass, sunglass, metal, gold, jewelry, diamond, watch

band, watch cover, watch hand

|

| textile |

spinneret plate, rubber parts, plastic molds, toy |

|

others

|

seal, flapper, coins, pottery, bank card, IGBT |

What’s anilox roller and how to clean it efficiently?

Cleaning the equipment and heavy duty products is a tough task that can’t be performed with simple tools. Due to the frequent use of the machine and electronic parts, deep cleaning is essential to give it proper and smooth function in every use, most of companies search for the technology, which covers the work in a easy way

Thanks to the advance developments in the field of technology and printing, that anilox rollers have gained a lot of popularity that a transfer roller. Mainly, anilox roller is a versatile tool in coating and decorative applications and right now it is being used to create prominent capacity whites and foundation coats, mainly for the stretchy packing, applying coatings, adhesives for the cold foil, coating for the images varnishes and other decorative purposes

It is a ceramic roller or an engraved metal roller mainly brought into use for the printing press to transfer the ink form the roller to the printing plate, its main purpose is to pick the ink from the roller or form any of the configurations and deliver a uniform amount of it to the robber plate for the printing process

It is mainly designed for most favorable ink release as a surface and it is laser fixed to reduce the porosity of cell wall and is strengthened by its ceramic subsurface, which benefits the printing quality, optimized cell profiles, improved consistency and more volumes of screen definition

It is mainly designed for most favorable ink release as a surface and it is laser fixed to reduce the porosity of cell wall and is strengthened by its ceramic subsurface, which benefits the printing quality, optimized cell profiles, improved consistency and more volumes of screen definition.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!