Separate Sweep Generator Control Immersible Ultrasonic Transducer Box 40khz SUS304

The generator is with sweep function.

Generally speaking, one transducers can control at most 3-5L water, and one generator can control at most 36pcs transducers. So customers can calculate the number of transducers that needed according to the tank capacity.

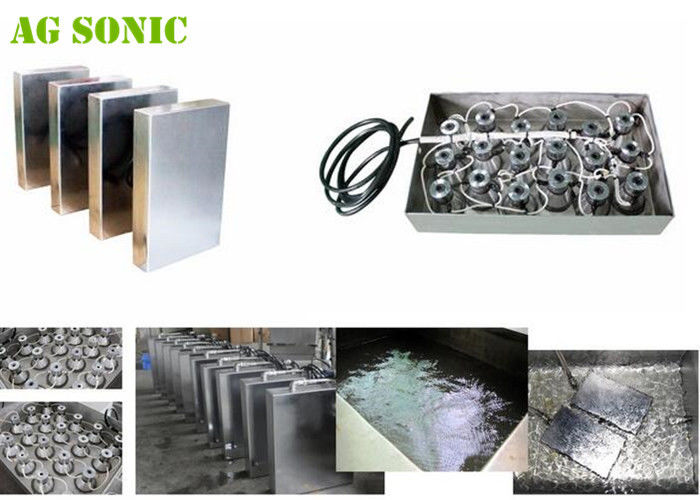

Ultrasonic Immersed transducers have the advantage of being easy to install, even in a tank which was not intended for that at the origin: they are simply placed or fixed in the tank and have the same cleaning effect as the transducers fixed directly on the tank.

Replacing of immersible transducers is easy.AG SONIC submersible transducers are designed for long life and optimum cleaning performance.

Submersible Ultrasonic cleaning systems:

- Allows existing tanks to be enhanced with ultrasonic cleaning capabilities

- Two mounting styles: bulkhead or riser.

- AG SONIC provides complete instructions and technical assistance Please note:

- Submersible systems are not suitable for use with plastic tanks

- Customers will be responsible for mounting of transducer packs purchased from AG SONIC.

Specifications:

| TZ-1003 |

SUS304/SUS316L |

3 |

15 |

250x150x100 |

Rigid tube/

Flexible tube |

28/40 |

150 |

| TZ-1006 |

6 |

30 |

305x250x100 |

300 |

| TZ-1012 |

12 |

60 |

355x250x100 |

600 |

| TZ-1018 |

18 |

90 |

406x305x100 |

900 |

| TZ-1024 |

24 |

120 |

500x355x100 |

1200 |

| TZ-1030 |

30 |

150 |

550x406x100 |

1500 |

| TZ-1036 |

36 |

180 |

500x460x100 |

1800 |

Features:

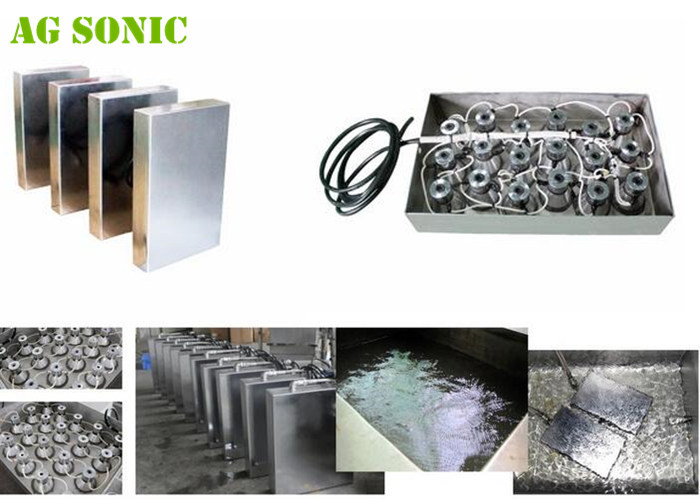

- Submersed in liquid, by bottom-mounting or wall-mounting

- Replaceable, expandable, renewable by submersible transducer module

- Customized to solve different problems with different frequency, power, shape, size etc accordingly

- Multi-frequencies are available by identical transducer or different models of transducer

- Full SUS304 to extand the lifespan

- For PCB,Electronic parts cleaning

Brief introduction of the submersible ultrasonic cleaning systems:

For customers who would like to improve the cleaning power of their existing tank by installing an ultrasonic cleaning device, AG SONIC's submersible system may be the most economical and efficient choice on the market.

However, before buying a submersible system, please consider the tank you already have and its material of construction.

Ideally, your existing tank should be manufactured of stainless steel or metal of some kind.

Plastic tanks are unsuitable for ultrasonic applications because they dampen the ultrasonic waves and so reduce the available ultrasonic cleaning power from anything between 60-90 per cent.

Submersible (or immersible) cleaning systems are powered by ultrasonic generators that are housed in transducer packs made from either 304 or 316 stainless steel. These packs contain a double stack of individual high-efficiency ultrasonic transducers. They are usually mounted to the bottom or the side walls of an existing tank so as to promote evenly-distributed ultrasonic cleaning in the tank in which they are submerged. The transducer packs come with special mounting tabs with holes and are designed to be attached permanently to the tank.

Submersible systems come with 28kHz, 40kHz, 80kHz, or CROSSFIRE Multiple Frequency Ultrasonic Systems.

The frequency you select will determine the size of the transducer pack you install. Most measure 3-4" tall and this corresponds to the amount of space that you will lose within your existing tank once the submersible cleaning system is installed.

Common Applications – Advantages of Immersible Ultrasonic Cleaning Transducers

- Drop in ultrasonics addition to existing manufacturing cleaning process lines (aqueous cleaning lines, passivation, plating lines, or other part finishing processes which require from microscopic surface scrubbing agitation)

- The stainless steel box heavy duty design with completely sealed components allow for precision ultrasonic cleaning in conditions normally too harsh for such precision electronics

- Valve bodies and manifolds with small internals not accessible for cleaning by forced spray or mechanical removal

- Medical device stainless steel parts cleaning

- Aerospace parts cleaning

- Ultrasonic part cleaning of water soluble machining coolants, chips, particulate, and true machining/cutting oils, buffing, polishing and lapping compounds which require mechanical surface scrubbing to remove.

- General washing for maintenance, manufacturing, rework and/or remanufacturing.

Applications:

| Industry |

|

Cleaning objects |

| machinery |

|

Moulds, precision parts, pressing parts, camera parts, bearing, hardware tools |

| electronics |

|

PCB board, electronic parts, TV parts, computer parts |

| Auto industry |

|

engine parts, gear box, shock absorber, auto nozzle, cylinder, valve |

| Plating& painting |

|

polishing parts, SUS cutter, tableware, plating |

| Food industry |

|

Oven tray, boiler, bottles, bottle cap, filters |

| Optical& watch maker |

|

optical lens, eyeglass, sunglass, metal, gold, jewelry, diamond, watch band,

watch cover, watch hand

|

| others |

|

seal, flapper, coins, pottery, bank card, IGBT |

FAQ:

How to install the ultrasonic transducers:

The immersible ultrasonic transducers can be mounted on the sides or bottoms of the parts washing/cleaning tanks, depending upon their geometry. In general, side mounting is recommended for tanks where the depth is more than two times the smallest of the length / width and side mounting the ultrasonics reduces the debris and foreign material from settling on the top of the transducer box which will reduce the ultrasonic effectiveness.

What to clean?

These submersible ultrasonics can be made in 25/28 kHz frequency, for tough to clean parts like engine blocks and mold cleaning burnt on carbon, and 40 kHz frequency for general parts cleaning including precision machined components, in an agitated immersion parts washer or stationary metal sided tanks. Immersibles are not typically added to polypropylene, PVC, PVDF or other plastic based tanks as the plastic absorbs the ultrasonic energy thereby reducing the cavitation energy delivered to the part surface.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!