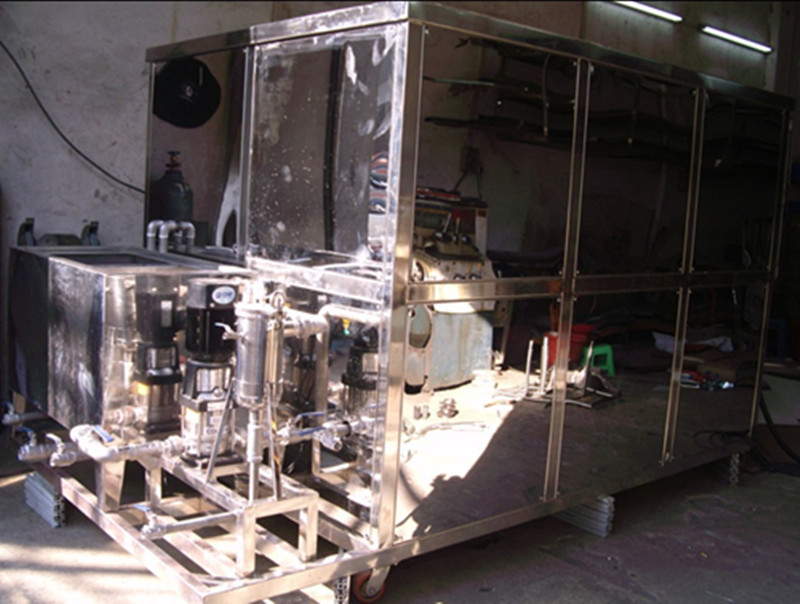

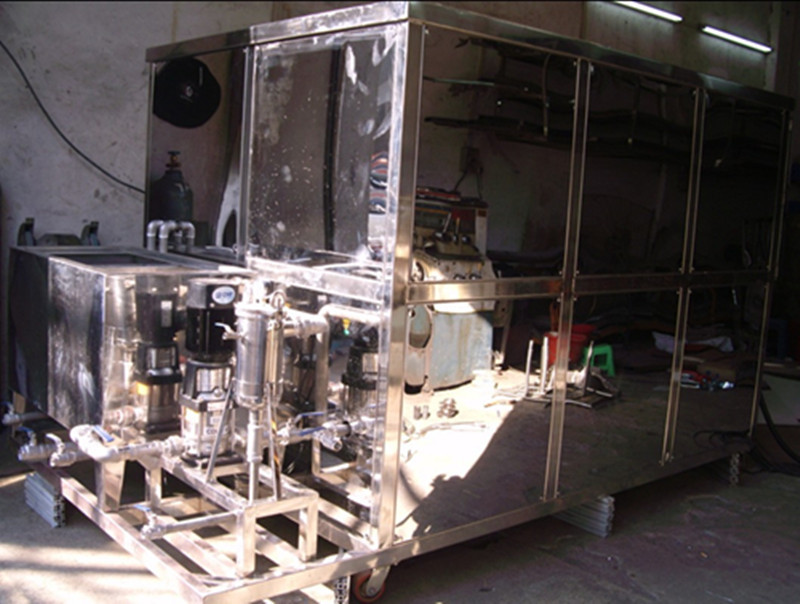

Stainless steel large industrial ultrasonic tank for marine parts and boat propellers

Heat is produced by ultrasonic cavitation and many cleaning tasks are faster and more efficient when using a heated solution.

For example, a hot cleaning solution is best for removing oils, machining coolants and a whole host of other contaminants from just about any surface you can think of.If this is the case for your requirements you can improve throughput by using ultrasonic cleaners with thermostat controlled heaters.

Larger ultrasonic tanks usually feature heavier duty wall construction and additional wall support. Heat may be supplied in a variety of ways including electric immersion heaters, steam coils, and/or external heat exchangers. Larger tanks may have either diaphragm-bonded transducers, or immersibles which are transducers bonded into a stainless steel can which is then mounted in the cleaning tank. The advantages of immersibles are that a can may be swapped out if required without the whole tank going down, and immersibles can often be retrofitted into existing process tanks to improve cleaning performance.

What ultraosnic can do ?

Automotive Ultrasonic Cleaners is primarily an aqueous tank systemthat uses ultrasonic energy to remove dirt, grease, oiland baked-on carbon from parts. Contaminants such aspaint, rust, glued-on gaskets, and heavy layers of bake don carbon can also be removed by ultrasonic cleaning but require more aggressive chemistries. Unlike someother cleaning processes, ultrasonic cleaning will notdamage intricate, lightweight, or easily damaged parts.

Ultrasonic cleaners remove dirt, oils, lubricants, carbon, rust,and other types of grime that build up on heat exchangers.

ultrasonic cleaners can restore heat exchanger to look and function like new.

Ultrasonic parts washers are particularly effective for metal parts; the gentle yet powerful process is much less damaging than traditional cleaning methods that use a brush and high-velocity chemical cleaning solutions. Ultrasonic cleaners use water based solutions that won’t damage filters yet reach every crack and crevice of the heat exchanger. Ultrasonic cleaning uses a process called cavitation where microscopic bubbles form from ultrasonic waves, then implode on the part’s components; thereby vigorously yet gently scrubbing and cleaning surfaces and crevices. No matter how stubborn the build-up, your heat exchanger tube will be restored to full working capacity.

Automotive Ultrasonic Cleaner by Cavitation Action

Cavitation action is described as the implosion of countless minute bubbles against surfaces of products immersed in the cleaning solution. Bubbles are created when generator-powered transducers bonded to the ultrasonic cleaner tank vibrate at ultrasonic frequencies measured in thousands of cycles per second or kilohertz (kHz).

Selecting the cleaning equipment is governed to a large extent by the size of molds being cleaned. Ultrasonic cleaners are available ranging from small benchtop units to industrial-sized floor-mounted equipment that can be fitted for automated cleaning and rinsing cycles. But do select a cleaner with a heater, timer and sweep mode.

Ultrasonics: The ONLY Way to Clean with Confidence

Regardless of the source of the dirt or contamination, AG Ultrasonic Cleaning Systems are designed to accommodate a wide variety of uses in diverse industries. Fast, effective and efficient, our machines will allow you to clean virtually any type of part or component. The following is just a short list of the many different types of items that have been cleaned using our systems.

-

Automotive (Car, Truck, Motorcycle) See Video Below

-

Aviation (Helicopters, Aircraft and Ground Support)

-

Personal Boat & Marine

-

Injection Molds

-

Restaurants, Bakeries & Kitchens (Oven Filters, Burners, Pots, Pans, Utensils)

-

Machines of All Types

-

Tools, Nuts, Bolts

-

Extrusion and Deburring

-

Almost anything made out of metal (ferrous and non-ferrous), plastic, vinyl, and wood.

Saved more than 20 labor hours and minimized employee chemical exposure.

AGSONIC wasn’t the cheapest or the most expensive. They had an excellent product for the money and a commitment to customer service. AGSONIC is very easy to work with, even from 2,000 miles away. The retrofit and all other support needs have been handled in a very responsive manner. AGSONIC ’ dependability and service are part of our operational success. As far as our employees and management are concerned, our AGSONIC units are here to stay. For any future needs, AGSONIC is our 1 choice.

– Customer feedbaack Aerospace.

How to Clean Large Automotive Ultrasonic Cleaner

Complex Automotive Ultrasonic Cleaner represent substantial investments by plastic injection molding companies which, in order to protect their investments, must establish cleaning procedures to remove a variety of stubborn contaminants. These include burned on residues, oils, flashing and grease that if allowed to remain will result in product rejection by the quality control department. Hand scrubbing with solvents simply does not do the job. In addition to being time consuming, manual cleaning introduces potential health hazards for personnel and solvent disposal challenges. The solution is using an ultrasonic cleaner instead of scrubbing in a solvent-based parts washer

What ultraosnic can do ?

Ultrasonic cleaners remove dirt, oils, lubricants, carbon, rust,and other types of grime that build up onengines and mechanical parts. Grooves, internal passageways, seals, and other hard to reach areas are cleaned easily, eliminating hours of disassembling and reassembling complex parts. Carburetors, pistons, cylinder heads, aluminum parts, and brake calipers are a few examples of components that are cleaned thoroughly with no manual scrubbing in an ultrasonic cleaner

Why Use Cylinder Head Engine Block Cleaning ?

Agsonics is renowned for their professional cleaning service to the motor industry.

How does ultrasonic cleaner technology clean?

Cavitation bubbles are vacuum cavities as tiny as red blood cells, or about 8 thousandths of a millimeter across. They are so small that it would take 1,250 of them lined up in a row to reach 1 cm long.

Under pressure of continuous vibration, these bubbles stretch and compress at a fast rate. Once they reach a certain size, as determined by the frequency and strength of the sound waves produced, the bubbles lose structural integrity and collapse violently. When these implosions happen near a surface, the bubbles emit high-powered streams of plasma that travel at more than 500 miles per hour and collide with, agitate and remove even very tiny particles and substances from that surface.

Auto Parts Cleaning machine

We are manufacturing and supplying of Automotive Ultrasonic Cleaners. We offer a wide range of ultrasonic cleaners. These are Single or Multistage Ultrasonic Cleaners, which are both manually operated & fully automated systems. Further, the machine is widely used and appreciated by our clients due to its professional dependability and user friendliness.

|

Specifications for ultrasonic cleaner T-288S

|

|

Model

|

T-288S

|

|

Tank capacity

|

1800L

|

|

Tank size

|

L150xW150xH80cm

|

|

Tank material

|

2mm SUS304

|

|

Ultrasonic power

|

14.4KW

|

|

Heating power

|

30KW

|

|

Timer

|

1-99min adjustable

|

|

Heater

|

0-80c adjustable

|

|

Frequency

|

28/40khz

|

|

Control

|

External generator, more stable

|

|

Optional

|

Oil filter system, pneumatic lift, rinsing tank, etc.

|

|

Voltage

|

110V, 1phase; 220V, 3phases/220V, 1phase; 380V, 3phases

|

|

Warranty

|

1 year

|

|

Packing

|

1unit/wooden case

|

Features of the machine:

• Low maintainence machine

• Heavy duty cleaning systems

• Chemical friendly- SS Rust proof body

• Industrial guage farication, build to last

• One year warrenty on any manufacturing defect

• Completely customized to suit the cleaning requirement

• Less human interfearance and less scope of error

• Accurate and uniform cleaning everytime

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!