80KHZ Immersible Ultrasonic Transducer Submersible Ultrasonic Cleaning Equipment

How are ultrasonic waves produced?

When high frequency sound waves are passed through a cleaning fluid such as water with a suitable detergent additive, many millions of microscopic bubbles form and collapse. These bubbles are the result of the stretch and compress phrases of the sound waves within the fluid, the whole process is known as cavitation. Micro-bubbles will implode under the mechanical action of ultrasonic waves and a large amount of energy will be released and the local temperature will increase. The bubbles are forced into crevices where the fluid can penetrate between the contamination and the workpiece and leaving it totally clean and free of hidden soils.

The different Ultrasonic Submersible Transducer frequencies

25 KHz - The most powerful frequency to remove strong pollution. Do NOT use on mirror polish surfaces and sensitive materials like glass, aluminum...

40 KHz - Standard frequency which can be compatible on a wide range of material and for removing a lot of pollution.

80 kHz - This frequency is used to clean parts with complex geometry. Cavitation bubbles can go into small holes to remove the pollution.

120 kHz and Megasonic - Main application in precision optics to clean very sensitive parts like wafers. The power of cavitation is low so these frequencies are used on clean parts to remove dust in final cleaning.

How ultrasonic systems work

When ultrasonic energy is introduced into a cleaning solution, it creates a pattern of alternating high and low pressure. The extreme low-pressure phase creates microscopic vacuum bubbles. During the subsequent high-pressure phases, the bubbles implode violently. This process is known as cavitation.

Cavitation provides an intense scrubbing action that leads to quick and consistent cleaning. It takes the standard practice of manual immersion and agitation to a much higher level. The bubbles are small enough to penetrate even microscopic crevices, allowing for cleaning in the most out-of-reach corners.

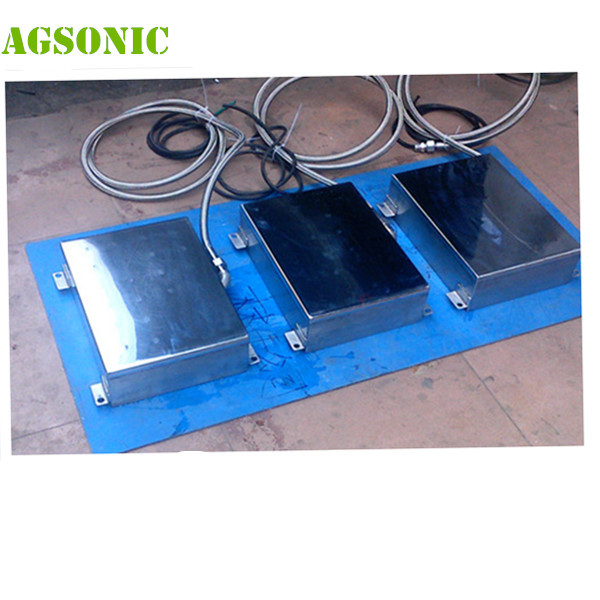

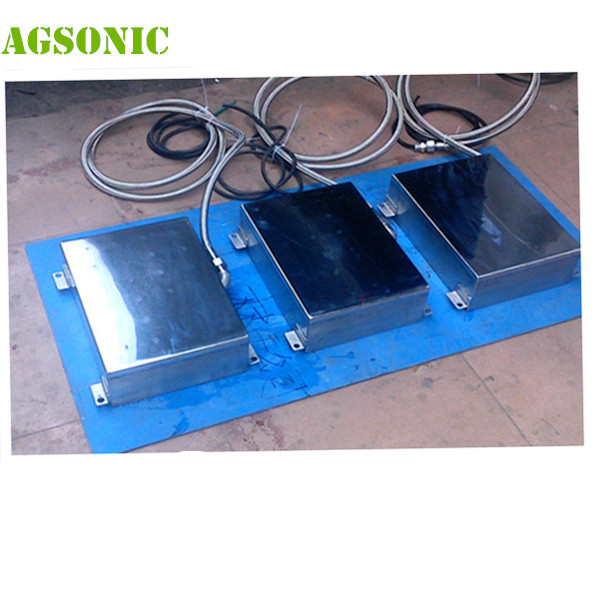

Our immersible transducer is custom designed for your particular application and tank size. It can be incorporated into existing tanks of any size and converted it into ultrasonic tank. It is controlled by our unique Pulse Swept Pleasecontact us for specific information on how we can create one for your Immersible Transducer needs.

The range of immersible transducers come in various sizes ultrasonic powers and operating frequencies. We can select the size you need based upon your cleaning requirements and tank size. The immersible ultrasonic transducer systems are portable and can be moved from one tank to another if required. They are most suited to when you have already a tank installed in your production process or we can supply the complete system including the tank.

Immersible ultrasonic transducers are designed for use in new or existing cleaning tanks to improve the speed and effectiveness of rinsing cleaning and other processes. Single or multi- module units can be custom designed for tanks of any size.

Common configurations:

Since submersible ultrasonic boxes are most commonly added to existing stainless steel and other metallic based tanks, the boxes and ultrasonic power are made to fit such tanks. We can easily make our immersible ultrasonics into any tank configuration sizing required for your application with little to no additional custom size pricing.

Brief Introduction of the immersible ultrasonic transducers:

Immersible ultrasonic transducers are sealed stainles steel enclosures which allow for adding ultrasonics to parts cleaning new tanks or adding onto existing tanks, equipment and systems.

The number and placement of the submersible Transducer Pack

There are pros and cons to both entry routes. Many customers prefer to buy the riser-style transducer packs because they do not want to make a hole in the bottom of their tank. The main disadvantage to using risers is that they may interfere with the cover or other system parts that are installed on the top. Most AGSONIC submersibles are custom manufactured in order to maximize the effectiveness of the ultrasonic system and to minimize possible dead spots. We are the only manufacturer to offer this service at no additional charge. We also have a line of standard ultrasonic submersible systems available.

If you think your existing cleaning tank may be suitable to adapt to ultrasonic cleaning please contact our technicians at AGSONIC and we will be pleased to provide you with more information and a quotation for a custom-made submersible system.

Immersible ultrasonic transducers do not require attachment to the tank (other than to hold them in position) to function efficiently. As a result, transducers can be moved from tank to tank and positioned as required for special applications when needed. Various mounting options are shown below.

Immersible transducer Types:

Bottom Monunted -over Top Junction Box

Bottom Mounted with dual Bulkhead

Bottom Mounted With single Bulkhead

Bottom Mounted With Over The Top Pipe

Side Mounted With Over the Top Pipe

Side Mounted With Bulkhead Thru Side Wall

Mounting may be either wall or bottom mounted, depending on the application. The units are shipped fully assembled and require only simple insertion into the tank prior to operation.

Specifications:

| Model |

Material |

Transducers |

Estimated volume |

Box size |

Cable

lead-out |

Ultrasonic frequency |

Ultrasonic power |

| (mm) |

(pcs) |

(L) |

(mm) |

|

(kHz) |

(W) |

| TZ-1003 |

SUS304/SUS316L |

3 |

15 |

250x150x100 |

Rigid tube/

Flexible tube |

28/40 |

150 |

| TZ-1006 |

6 |

30 |

305x250x100 |

300 |

| TZ-1012 |

12 |

60 |

355x250x100 |

600 |

| TZ-1018 |

18 |

90 |

406x305x100 |

900 |

| TZ-1024 |

24 |

120 |

500x355x100 |

1200 |

| TZ-1030 |

30 |

150 |

550x406x100 |

1500 |

| TZ-1036 |

36 |

180 |

500x460x100 |

1800 |

Enhance the cleaning power of your existing tank with AGSONIC Submersible Ultrasonic Cleaning Systems

For customers who would like to improve the cleaning power of their existing tank by installing an ultrasonic cleaning device, AGSONIC's submersible system may be the most economical and efficient choice on the market.

However, before buying a submersible system, please consider the tank you already have and its material of construction.

Technical Specifications

Ultrasonic transducer elements sealed in a liquid-tight housing are an option to transducer elements permanently bonded to the side or bottom of a cleaning tank. The major benefits of immersible ultrasonic transducers are that they are easy to service and can be added to existing equipment, often without extensive tank modifications. Ultrasonics unique technology is offered in the immersible transducer format. This includes standard individual frequencies from 28 kHz to 120 kHz as well as multiple frequencies in a single or multiple units.

FAQ

Understanding Ultrasonic Power

When an ultrasonic cleaner is running electrical power is consumed evenly but it is released in intervals to create the sound waves that shape the ultrasonic signal. Some manufacturers report ultrasonic peak power, others report average power, and some report both.

When comparing equipment you must compare based on the same criterion otherwise you’d be comparing apples with oranges.

While more power usually indicates faster and more effective cleaning, more power is not always better.

Too much power can damage electronic parts, the surface finish on a soft metal (e.g. aluminum), and other delicate items.

For cleaning extremely sensitive items, adjustable power is a useful feature.

Keep in mind that the larger the volume of solution, the more ultrasonic power will be needed for cleaning.

Most cleaners run at an average power of 50 to 100 watts per gallon, so the larger the tank the more power you need.Don’t attempt to increase the effective power of an ultrasonic cleaner by under-filling the tank.

Ultrasonic cleaner generators that power transducers are tuned to a particular fill level.

Operating the unit with less fluid can damage the generator and will result in less than optimized cleaning.

Why Ultrasound?

It’s efficient, clean, green and cost-effective.

Most importantly, it works.

A powerful cleaning solution is now as simple as soap, water and some mighty little bubbles.

Ultrasonic cleaning technology is fast, gentle and extremely powerful. It uses microscopic cavitation bubbles and specially

formulated eco-friendly solutions to search every crease and crevice and eliminate even stubborn or difficult-to-reach contaminants, including grease, dirt, hydrocarbons, metal

shavings, buffing/polishing compounds, carbon deposits, mold release and more.

Ultrasonic technology uses absolutely no harmful chemicals.

No fumes. No strong odors. No dangerous or expensive chemical disposal. Reduced risk.

The technology is remarkable, but the process is easy. More efficient and effective than chemical processes, the

machines are as simple to use as a dishwasher, with no hand labor or supervision necessary.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!