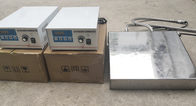

Brief Introduction of the immersible ultrasonic transducers:

Immersible ultrasonic transducers are sealed stainless steel enclosures which allow for adding ultrasonics to parts cleaning new tanks or adding onto existing tanks, equipment and systems.

The number and placement of the submersible Transducer Pack

Common Applications – Advantages of Immersible Ultrasonic Cleaning Transducers

· Drop in ultrasonics addition to existing manufacturing cleaning process lines (aqueous cleaning lines, passivation, plating lines, or other part finishing processes which require from microscopic surface scrubbing agitation)

· The stainless steel box heavy duty design with completely sealed components allow for precision ultrasonic cleaning in conditions normally too harsh for such precision electronics

· Valve bodies and manifolds with small internals not accessible for cleaning by forced spray or mechanical removal

· Medical device stainless steel parts cleaning

· Aerospace parts cleaning

· Ultrasonic part cleaning of water soluble machining coolants, chips, particulate, and true machining/cutting oils, buffing, polishing and lapping compounds which require mechanical surface scrubbing to remove.

· General washing for maintenance, manufacturing, rework and/or remanufacturing.

Immersible ultrasonic transducers do not require attachment to the tank (other than to hold them in position) to function efficiently. As a result, transducers can be moved from tank to tank and positioned as required for special applications when needed. Various mounting options are shown below.

Immersible transducer Types:

Bottom Monunted -over Top Junction Box

Bottom Mounted with dual Bulkhead

Bottom Mounted With single Bulkhead

Bottom Mounted With Over The Top Pipe

Side Mounted With Over the Top Pipe

Side Mounted With Bulkhead Thru Side Wall

Mounting may be either wall or bottom mounted, depending on the application. The units are shipped fully assembled and require only simple insertion into the tank prior to operation.

Specifications:

| Model |

Material |

Transducers |

Estimated volume |

Box size |

Cable

lead-out |

Ultrasonic frequency |

Ultrasonic power |

| (mm) |

(pcs) |

(L) |

(mm) |

|

(kHz) |

(W) |

| TZ-1003 |

SUS304/SUS316L |

3 |

15 |

250x150x100 |

Rigid tube/

Flexible tube |

28/40 |

150 |

| TZ-1006 |

6 |

30 |

305x250x100 |

300 |

| TZ-1012 |

12 |

60 |

355x250x100 |

600 |

| TZ-1018 |

18 |

90 |

406x305x100 |

900 |

| TZ-1024 |

24 |

120 |

500x355x100 |

1200 |

| TZ-1030 |

30 |

150 |

550x406x100 |

1500 |

| TZ-1036 |

36 |

180 |

500x460x100 |

1800 |

Features:

1. Submersed in liquid, by bottom-mounting or wall-mounting

2. Replaceable, expandable, renewable by submersible transducer module

3. Customized to solve different problems with different frequency, power, shape, size etc accordingly

4. Multi-frequencies are available by identical transducer or different models of transducer

5. Full SUS304 to extand the lifespan

IMMERSIBLE TRANSDUCERS

Simultaneous Multi- Frequency Immersibles are constructed of cavitation resistant, bright annealed, 316L stainless steel with robotically welded seams to ensure a long life. The Ceramically Enhanced Bar design consists of two transducer stacks which permit simultaneous multiple frequencies. They are available in the form of transducerized tanks and separate immersibles which are fully sealed so they can be inserted into an existing tank to convert it into an ultrasonic cleaning system. Immersible transducers are a perfect way to introduce ultrasonic energy into existing tanks. Also, the units are easily replaceable for economical repairs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!