Mold Remediation Industrial Ultrasonic Cleaner with Water Recycle AG-180G

Brief introduction of the 61 Lindustrial ultrasonic cleaner:

To reduce the material cost, AG SONIC has standardized 38L-360L ultrasonic cleaner, so you can get the machine in short time and low price. For more info, welcome to ask.

1. The machine is with digital timer and heater, so it's easy for you to handle the machine;

2. The machine is with separate generator, so it's much more stable than the one with built-in PCB. And it's easy for you to change the PCB if any problem. On the other hand, it will reduce the packing size, so the shipping freight will be much lower.

3. The machine is with casters compared with 30L betchtop ultrasonic cleaner, so it will easy to move in the factory if full with water.

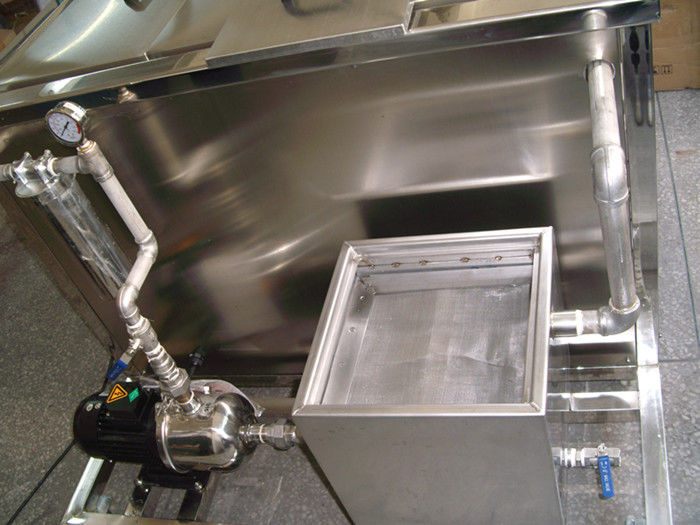

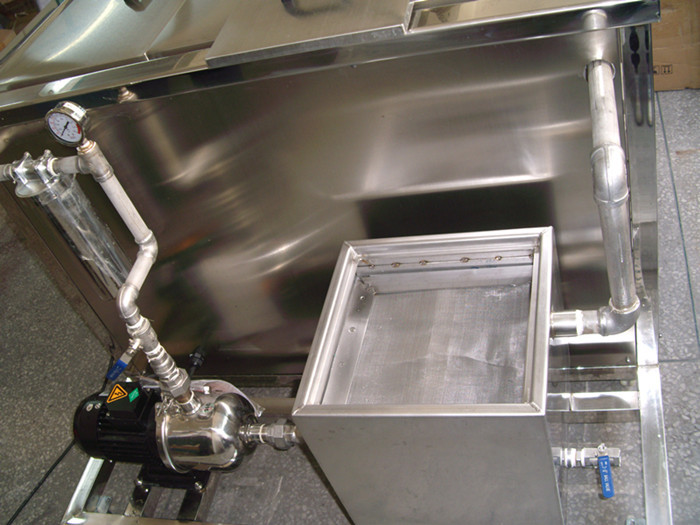

4. The machine is with water recycle system to recycle the solvent and absorb the oil.

5. The machine will be packed in wooden case, and you can get the machine in good condition.

Application

Ultrasonic cleaning can be used for many applications, including plastic parts, bearing, bolts, rubber parts, internal parts, plastic injection molds, transmission parts, and final cleaning of all engine parts prior to assembly, the versatility of ultrasonic cleaning machine make them the perfect choice for automotive, medical, pharmaceutical, aerospace, engineering and many other industries

Characters

Opposing horizontal transducers mounted at two sides

Digital control wave ultrasonic generators

Movable cleaning basket

Can combined with lifting system, drying tank, rinsing tank, recirculation & filtering system

Incredible versatility in dimension, function and auxiliary couples

Why clean parts with ultrasonic?

Delivering and using clean parts is not always obvious, certainly, no one wants to handle a dirty parts or install it into a critical machine, but, dirty, debris and contaminants can cause problems for manufactures and end users, from the merely frustrating to catastrophic, dirty parts can cause critical components to exceed tolerances and even fail damaging valuable equipment and property while contamination (everything from grease, oil and chemicals to viruses and bacteria) can seriously harm users.

Here at AG we know about industrial production.

During production and further processing of material goods or merchandise in factories and plants, a wide range of cleaning tasks apply. Precision is required here (as well). Only clean parts without residue can be coated, varnished, glued or soldered. For this reason, professional parts cleaning before further machining or processing as well as final cleaning before delivery is required for the production of high-quality parts and assemblies. Even during component and assembly overhaul, our cleaning systems are being used before and after maintenance for quality control and conservation of value of the parts. Our ultrasonic cleaners and systems are used in industries like electronics, micromechanics, metalworking industry or aviation.

Specifications:

| Specifications for ultrasonic cleaner AG-180G with oil filter system |

| Model |

AG-180G |

| Tank capacity |

61L |

| Tank size |

500x350x350mm |

| Unit size |

640x490x570mm |

| Tank material |

2mm SUS304 |

| Ultrasonic power |

900W |

| Heating power |

1.5KW |

| Timer |

1-99min adjustable |

| Heater |

0-80c adjustable |

| Frequency |

28/40khz |

| Control |

External generator, more stable |

| Optional |

Oil filter system, pneumatic lift, rinsing tank, etc. |

| Voltage |

110V, 1phase; 220V, 3phases/220V, 1phase; 380V, 3phases |

| Warranty |

1 year |

| Packing |

1unit/wooden case |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!