To Clean Cooiling Channels Core Cavity Inserts Ejectors Maintenance Mould Ultrasonic Cleaner

Plastic Mold Cleaning by Cavitation Action

Cavitation action is described as the implosion of countless minute bubbles against surfaces of products immersed in the cleaning solution. Bubbles are created when generator-powered transducers bonded to the ultrasonic cleaner tank vibrate at ultrasonic frequencies measured in thousands of cycles per second or kilohertz (kHz).

Selecting the cleaning equipment is governed to a large extent by the size of molds being cleaned. Ultrasonic cleaners are available ranging from small benchtop units to industrial-sized floor-mounted equipment that can be fitted for automated cleaning and rinsing cycles. But do select a cleaner with a heater, timer and sweep mode.

The process is fairly straightforward regardless of equipment size. Here’s a simplified description that can be modified based on your specific operations:

- Fill the ultrasonic cleaner with water but allow room for cleaning solution displacement due to the size of the molds being cleaned. Add the proper amount of biodegradable cleaning solution concentrate.

- When you are ready to clean place the injection molds in the cleaner basket. Take care that they do not contact each other. If you are cleaning large parts you may suspend them in the cleaning solution so they do not contact the tank bottom. Some industrial cleaners are equipped with bottom racks to support products being cleaned.

- Set the heater to 65 C and timer from 10 to 60 minutes depending on the degree of contamination. Activate the sweep mode to assure uniform distribution of cavitation and promote uniform cleaning then lower the molds into the solution. With experience you will establish optimum cleaning conditions.

- At the end of the cycle remove the molds and inspect. When satisfied, rinse them with fresh hot water and allow them to dry or blow them dry with compressed air. Note that intricate configurations and cavities may trap water that should be removed by adding an electric drying oven to your setup.

Rinsing tip: You’ll want to thoroughly remove cleaning solution residues. Complex shapes may call for a spray rinse or, in certain cases, rinsing by cavitation in an ultrasonic rinse tank.

How to Clean Large Plastic Injection Molds

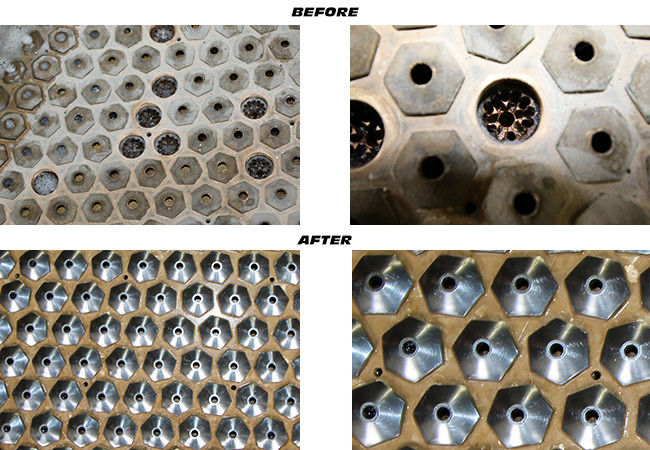

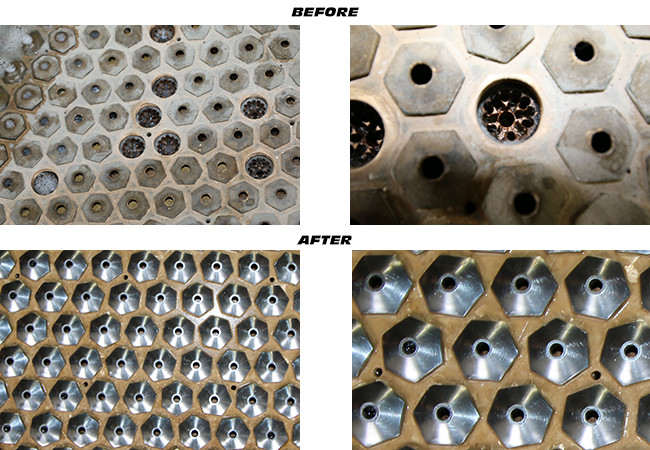

Complex molds require careful cleaning.

Complex injection molds represent substantial investments by plastic injection molding companies which, in order to protect their investments, must establish cleaning procedures to remove a variety of stubborn contaminants. These include burned on residues, oils, flashing and grease that if allowed to remain will result in product rejection by the quality control department. Hand scrubbing with solvents simply does not do the job. In addition to being time consuming, manual cleaning introduces potential health hazards for personnel and solvent disposal challenges. The solution is using an ultrasonic cleaner instead of scrubbing in a solvent-based parts washer.

Why an Ultrasonic Cleaner is Ideal for Injection Molding

In three words: thorough, safe and fast. Contaminants missed by manual cleaning are usually those deep in crevices and on other surfaces impossible to reach. Moreover, highly finished mold surfaces can be scratched or otherwise damaged by manual processes. Large molds can be difficult to maneuver, further risking damage during manual cleaning. And the longer it takes to clean the molds the greater the risk of damage.

Ultrasonic cleaning action solves all three issues.

It is thorough because it reaches all mold surfaces immersed in a biodegradable water-based ultrasonic cleaning solution. It is safe because while the cleaning action can be termed “violent” it occurs so fast that highly polished injection mold surfaces are not damaged during the cleaning process. By fast we mean 10 to 15 minutes although large complex molds may require a longer cleaning cycle.

Ultrasonics: The ONLY Way to Clean with Confidence

Regardless of the source of the dirt or contamination, AG Ultrasonic Cleaning Systems are designed to accommodate a wide variety of uses in diverse industries. Fast, effective and efficient, our machines will allow you to clean virtually any type of part or component. The following is just a short list of the many different types of items that have been cleaned using our systems.

- Automotive (Car, Truck, Motorcycle) See Video Below

- Aviation (Helicopters, Aircraft and Ground Support)

- Personal Boat & Marine

- Injection Molds

- Restaurants, Bakeries & Kitchens (Oven Filters, Burners, Pots, Pans, Utensils)

- Machines of All Types

- Tools, Nuts, Bolts

- Extrusion and Deburring

- Almost anything made out of metal (ferrous and non-ferrous), plastic, vinyl, and wood.

ultrasonic tank models for your choice:

| Model |

Tank size |

Unit size |

Volume |

Ultrasonic power |

Frequency |

Heating power |

Timer |

Heating temperature |

| LxWxH(mm) |

LxWxH(mm) |

(L) |

(W) |

(kHz) |

(KW) |

(MIN) |

(℃) |

| T-12S |

500x300x250 |

640x440x470 |

38 |

600 |

28/40 |

1.5 |

1-99 |

0-80

|

| T-18S |

500x350x350 |

640x490x570 |

61 |

900 |

1.5 |

| T-24S |

550x400x400 |

690x540x620 |

88 |

1200 |

3 |

| T-30S |

600x450x400 |

740x590x620 |

108 |

1500 |

3 |

| T-36S |

600x500x450 |

740x640x670 |

135 |

1800 |

4.5 |

| T-48S |

700x500x500 |

840x640x720 |

175 |

2400 |

6 |

| T-60S |

800x600x550 |

940x740x770 |

264 |

3000 |

7.5 |

| T-72S |

1000x600x600 |

1140x740x820 |

360 |

3600 |

9 |

Main Features

1) Tank materail is SUS304 with 2mm thickness, Human hand argon welded, Sturdy and durable resistance to high tempearture

2) 50W industrial transducers, outstanding cleaning effects

3) External ultrasonic generator

4) Power adjustable, choose different power according to different cleaning objects

5) Digital timer: 1~99hours timer adjustable. continious working for long time.

6) With memory function, no need to reset time and temperature every time.

7) 20~80C adjustable, 9KW heating panel, faster cleaning

8) Industry use power cord, more safer.

9) Can bear 50~100KG cleaning objects

10) Accessories: Machine with stainless steel basket, drainage, lid, movable castors.

Q - How much ultrasonic power do I need in my cleaning tank? Can I have too much power?

The right amount of ultrasonic energy (usually expressed in watts per gallon) depends on the size of the cleaning bath and the difficulty of the cleaning requirement. Tanks in the one to two gallon size range often provide up to 200 watts per gallon of ultrasonic power. Achieving the same cleaning effect in larger tanks requires less energy density. Excellent cleaning has been demonstrated in tanks having 2,000 gallons capacity with only 5 to 7 watts per gallon. The more difficult the application, the greater energy density is required for effective cleaning. Too much ultrasonic power may result in cavitation erosion occurring on delicate or highly polished parts that are near the transducer radiating surface. Aluminum, copper, brass and other soft metals are especially susceptible to cavitation erosion.

Q - Can ultrasonics cause damage to hearing? Are there any other effects on the body?

Ultrasonic cleaning equipment utilizes high energy sound waves at frequencies above those audible to humans to enhance the chemical and mechanical cleaning effects of liquids. The ultrasonic energy, although high in power, has no measurable impact on human auditory senses - in fact, there are no established time weighted average exposure limits for frequencies above 20kHz (20,000 cycles per second) . The frequencies of concern are the audible sub-harmonics of the ultrasonic primary frequency. These are produced due to sympathetic resonance of various components of the ultrasonic equipment which may include the cleaning tank, the enclosure panels, lids and other features. Pumps, blowers, and other ancillary equipment also contribute to the overall noise produced by the unit. In that regard, ultrasonic cleaning equipment is no different than a machine tool or any other piece of equipment found in the industrial environment. Ultrasound of the intensity that can be transmitted through the air has no known effect on body tissue. Ultrasound, in fact, is commonly used for imaging of the human body.

Blow Molds Ultrasonic Cleaning Machine 3 tank

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!