Double Machine With A Foot Automatic Used Fuel Pump And Injectors Auto Sonic Cleaner

Suitable for All Types of Engine Parts Fuel Pump And Injectors Auto

AGSONIC’s ultrasonic cleaners effectively and thoroughly clean all types of engine parts:

- Automotive: Thoroughly removes carbon deposits, grease, and other types of dirt and contaminants from carburetors, exhaust manifolds, cylinder blocks, 2-stroke and 4-stroke motorcycle engines, snow machines, ATV cylinders and heads, and more.

- Marine: Suitable for inboard and outboard motors, the cleaning chemistry is both thorough and gentle on aluminum parts, reducing the risk of future corrosion.

- Aircraft: The high performance demands of aircraft engines establish the need for an intensive cleaning process that will restore the engine part to near original condition. Our ultrasonic units easily, thoroughly, and safely clean both large and small parts. Turbine blades, fuel nozzles, generator components, brakes and other parts that require periodic cleaning are all effectively and thoroughly cleaned using the ultrasonic cleaning process.

We are manufacturing and supplying of Automotive Ultrasonic Cleaners. We offer a wide range of ultrasonic cleaners. These are Single or Multistage Ultrasonic Cleaners, which are both manually operated & fully automated systems. Further, the machine is widely used and appreciated by our clients due to its professional dependability and user friendliness.

Ultrasonic Cleaning system Design:

Considerations in the design of any cleaning system include the contaminants on the part(s), the required cleanliness level, the geometry and material of the part(s), the quantity to be processed, and the previous system design and layout (if applicable). The part geometry, production rate, and cleaning time required will determine the size of the cleaning system, once the overall process has been decided

When Should I Clean My Fuel Pump And Injectors Auto ?

Cleaning your Fuel Pump And Injectors Auto should be done when suggested by the manufacturer. Neglect of cleaning your filter will lead to “regeneration” too frequently, causing you to lose miles per gallon or power.Fuel Pump And Injectors Auto regeneration is the process by which the Fuel Pump And Injectors Auto removes diesel particulate matter from the exhaust gas and burns off the matter. This process occurs at highway speeds above 40mph. Your Fuel Pump And Injectors Auto will become saturated during normal use causing it to regenerate too often. Vehicles that operate at speeds less than 40 mph tend to not regenerate properly. This will cause the Fuel Pump And Injectors Auto to become saturated at a faster rate

How does ultrasonic filter cleaning work?

Don’t replace filters when they become clogged with dirt, grease or other contaminants; ultrasonic cleaners can restore many types of filters to look and function like new. Ultrasonic parts washers are particularly effective for filters made of metal or plastic mesh; the gentle yet powerful process is much less damaging than traditional cleaning methods that use a brush and high-velocity chemical cleaning solutions. Ultrasonic cleaners use water based solutions that won’t damage filters yet reach every crack and crevice for the best possible clean. Ultrasonic cleaning uses a process called cavitation where microscopic bubbles form from ultrasonic waves, then implode on the part’s components; thereby vigorously yet gently scrubbing and cleaning surfaces and crevices. No matter how stubborn the build-up, your filters will be restored to full working capacity.

Why Clean Parts with Ultrasonics?

Delivering and using clean parts is not always obvious. Certainly, no one wants to handle a dirty part or install it into a critical machine, but dirt, debris and contaminants can cause problems for manufacturers and end users. From the merely frustrating to catastrophic, dirty parts can cause critical components to exceed tolerances and even fail damaging valuable equipment and property while contamination (everything from grease, oil and chemicals to viruses and bacteria) can seriously harm users.

Benefits of ultrasonics for Fuel Pump And Injectors Auto :

- Cleans delicate parts without damage

- Cleans cracks and crevices that would be difficult to reach with the hand

- Does not require line-of-sight for effective cleaning

- Doesn’t use harsh chemical solvents that are dangerous for workers and the environment

- Safe for aluminum, magnesium and zinc

- Biodegradable cleaner

- Clean multiple pieces at once without having to brush by hand – saves time and money

We know that your reputation depends on cleaning Fuel Pump And Injectors Auto effectively and efficiently. Ultrasonics International can help you choose the right kind of ultrasonic cleaner, training and support that you need for your business needs.

For more than two decades, Ultrasonics has helped businesses improve profitability by providing their clients with ultrasonic cleaning equipment that feature the latest advancements in wave sweep technology. Our ultrasonic cleaning equipment has a reputation for reliability and longevity. Utilizing the proper ultrasonic cleaning equipment saves money and improves cleaning processes. Cleaning results will be measurably better and less time will be required to complete the cleaning process.

Pls find more specifications below:

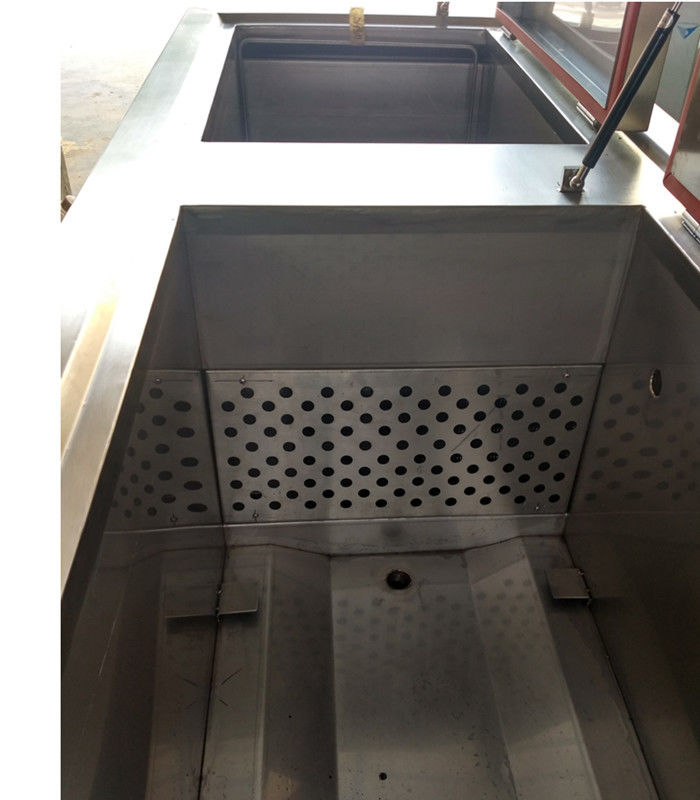

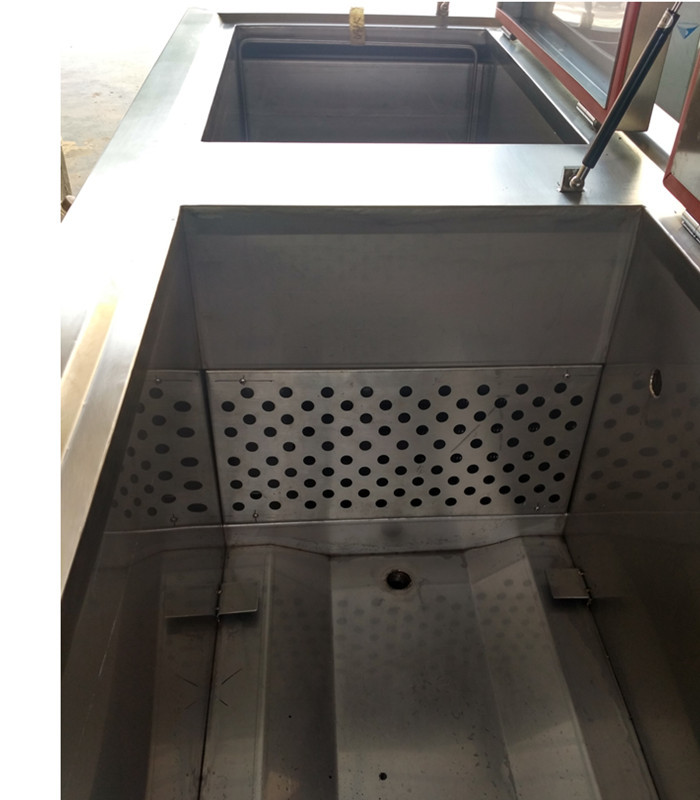

Specifications:

| Model |

T-2048G |

T-2072G |

T-2144G |

| Ultrasonic Tank Dimension(mm) |

550X400X350 |

600X500X450 |

1000X600X600 |

| Rinsing tank dimension(mm) |

550X400X350 |

600X500X450 |

1000X600X600 |

| Max. Capacity |

77L/tank |

135L/tank |

175L/tank |

| Construction Case |

SUS304 (Mirror shining image available) |

| Construnction Tank |

SUS304 |

| Transducer Number |

48pcs |

72pcs |

144pcs |

| Ultrasonic power(Max.) |

2400W |

3600W |

7200W |

| Ultrasonic frequency |

40kHz |

40kHz |

40kHz |

| Temperature range |

20~80C adjustable |

|

|

| Heating power |

6KW |

12KW |

24KW |

| Timer |

1~99h |

1~99h |

1~99h |

| Drain |

3/4" Valve |

|

|

| Lid & Basket |

Available, material: SUS304 |

|

|

| Cleaning Tank voltage |

AC220V/AC380V 3phase |

|

|

| Generator Voltage |

AC110V / 220V 1phase |

|

|

| Features |

With double tank for cleaning and rinsing.

With filtration system

Multi-direction castors with brake;

1 year warranty |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!