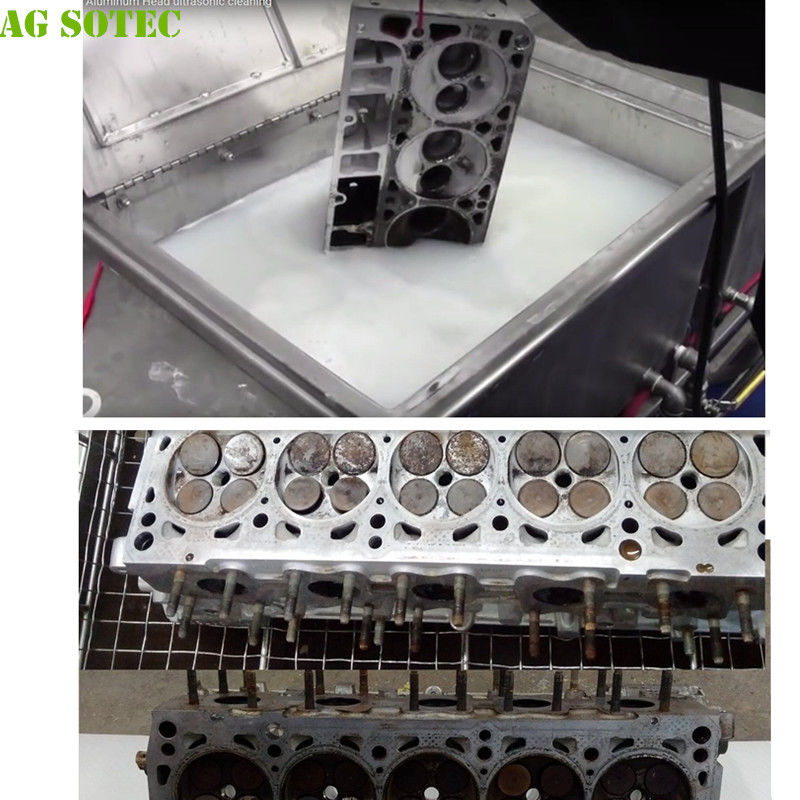

Engine Ultrasonic Cleaner Exhaust Gas Aftertreatment, Cooled Exhaust Gas Recirculation (EGR) System Diesel

The cleaning scope of AG Engine block ultrasonic cleaning machine

Suitable for all types of engine parts

AG engine block ultrasonic cleaning machine effectively and thoroughly clean all types of engine parts

01: Automotive: thoroughly removes carbon deposits, grease, and other types of dirty and contaminants from carburetor, exhaust manifolds, cylinder blocks, 2-stroke and 4 stroke motorcycle engines, snow machines, ATV cylinders and heads, and more.

02: Marine: Suitable for inboard and outboard motors, the cleaning chemistry is both thorough and gentle on the aluminum parts reducing the risk of future corrosion

03: Aircraft: The high performance demands of aircraft engines establish the need for an intensive cleaning process that will restore the engine part to near original condition, our engine block ultrasonic cleaning machine easily, thoroughly, and safely clean both large and small parts, turbine blades, fuel nozzles, generator components, brakes and other parts that require periodic cleaning are all effectively and thoroughly cleaned using the ultrasonic cleaning process

Machine equipment system includes replaceable transducer box and generator. The transducer box and generator can be both build-in or separate but work together to operate ultrasonic cleaning process with transducer box immersible mounted in fluid tank, one side or both side or bottom mounted inside the tank. The number and placement of transducers is selected to give maximum results in any parts cleaning tank with any cleaning load. Specification of tank dimension and transducer boxes are custom made available. Either for mould of parts cleaning can receive perfect cleaning efficiency. Stainless steel basket is optional.

Application in Diesel Particulate Filter washing car part and metel part as below.

Automatic manufacturing semi-product and product cleaning

Automatic repair cleaning including engine,gear box,connecting rod,oil pump,crust,disc break,turbo supercharger,fuel injector,gearing,bearing and other components

Cleaning product after processing by boring and grinding machines

Ideal for car parts washing, engine block cleaning,workshop sonic bath cleaning.

Ideal to clean rust,carbon,pait,heavy oil, without damage to parts inside tank with suitable cleaning liquid.

Engine Parts Cleaning, Car Engine Parts Cleaning, Truck Engine Parts Cleaning, Motor Bike Engine Parts Cleaning.

AGSONIC specialising in providing Ultrasonic cleaning services and products to the industrial sector utilising the latest ultrasonic cleaning technology.

The Engine Parts division specialises in the Ultrasonic Cleaning of Engine Parts, Car engine parts, Truck engine parts and Motor bike engine parts to both trade customers and individuals throughout the World.

Our Ultrasonic cleaning process, can effectively clean the following components- Aluminum castings, engine blocks, Carburetors, Cylinder Heads, Engines, Engine Components, Gear Boxes, Filters, Tubes and Valves.

AGsonic ultrasonic cleaner machine

| Industry |

Cleaning objects |

| jewelry |

Jewelry, diamond, gold, silver products, |

| machinery |

Moulds, precision parts, pressing parts, camera parts, bearing, hardware tools |

| electronics |

PCB board, electronic parts, TV parts, computer parts |

| Auto industry |

engine parts, gear box, shock absorber, auto nozzle, cylinder, valve |

| Dental& Medical |

dental tools, medical tools, injector, surgery tools, dropper, glass container |

| Plating& painting |

polishing parts, SUS cutter, tableware, plating |

| Food industry |

Oven tray, boiler, bottles, bottle cap, filters |

| Optical& watch maker |

optical lens, eyeglass, sunglass, metal, gold, jewelry, diamond, watch band, watch cover, watch hand |

| textile |

spinneret plate, rubber parts, plastic molds, toy |

| others |

seal, flapper, coins, pottery, bank card, IGBT |

AGsonic make rinsing tanks and dryer tanks to dryer after rinsing, such as for tank capacity of 50L,100L,150L,200L or even bigger tank. Multi tanks with different functions by each unit work together to approach maximum cleaning efficiency.

Take 3-tank ultrasonic cleaner as example:

1st ultrasonic cleaning tank

2nd rinsing tank after rinsing(or add a second rinsing tank for thorough rinsing)

3rd dryer tank

Specification details as follows:

1st ultrasonic tank: installed with ultrasonic cleaning transducers to operate cleaning process by ultrasonic transducer vibration.

2nd Rinsing tank: It has a continues supply of water by supplying water from the bottom, and dirty liquid flow away from the surface of the liquid.

Specification details:

Single tank models for your choice:

| Model |

Tank size |

Unit size |

Volume |

Ultrasonic power |

Frequency |

Heating power |

Timer |

Heating |

|

| LxWxH(mm) |

LxWxH(mm) |

(L) |

(W) |

(kHz) |

(KW) |

(MIN) |

(℃) |

|

| T-12S |

500x300x250 |

640x440x470 |

38 |

600 |

28/40 |

1.5 |

1-99 |

0-80

|

|

| T-18S |

500x350x350 |

640x490x570 |

61 |

900 |

1.5 |

| T-24S |

550x400x400 |

690x540x620 |

88 |

1200 |

3 |

| T-30S |

600x450x400 |

740x590x620 |

108 |

1500 |

3 |

| T-36S |

600x500x450 |

740x640x670 |

135 |

1800 |

4.5 |

| T-48S |

700x500x500 |

840x640x720 |

175 |

2400 |

6 |

| T-60S |

800x600x550 |

940x740x770 |

264 |

3000 |

7.5 |

| T-72S |

1000x600x600 |

1140x740x820 |

360 |

3600 |

9 |

Features:

Adjustable ultrasonic power

Original BLT type transducer

SUS 316L stainless steel tank

Adaptable for continuous operation

Adjustable thermo controller

Adjustable ultrasonic power

With separate control ultrasonic electronic generator

sweep mode control available

digital timer & heating control

boost mode& oil skimmer upon clients requirement

pressure pump and filter system are available

Competitive Advantage:

- Adjustable ultrasonic power

- Original BLT type transducer

- dual frequency 40 and 120khz for different cleaning items, gentel but powerful

- SUS304/316L tank

- Adaptable for continuous operation

- Adjustable thermo controller

FAQ:

Q: What’s advantage of ultrasonic cleaner?

A: ultrasonic cleaner is the best way to have thorough cleaning without damaging objects. It helps to

remove stubborn dirt and dust from watch, eyeglasses, jewelry, etc, make them look new once again.

It’s very safe and easy to operate, proves to be a best helping hand for you at home.

Q: How often should I change the cleaning fluid in my tank?

A: Changed whenever it becomes visibly too contaminated, or when the cleaning process is not as effective.

Q: Why do I need to use a basket?

A: Basket would help to load objects together, and get better cleaning effect.

Q: Can ultrasonic cleaning damage parts?

A: Although the effect of thousands of implosions per second is very powerful, the cleaning process is safe.

No damage to your daily objects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!