High Power Transducer Pipe Bar Tuning And Piece Machining Ultrasound Cleaning

Large-capacity Industrial Ultrasonic Cleaners

Powerful Industrial Ultrasonic Cleaner

The largest ultrasonic tanks can include tanks as big as 1,000 gallons or more. These units are meant for applications requiring lower frequencies (25-40 kHz), including larger or heavy duty equipment such as over-sized manufacturing parts, automotive and marine parts and large musical instruments. Units may have multiple built-in stages, including rinse and dry stations, and are sometimes automated.

We all want to look our car shiny, and running smooth. And for this very reason timely servicing your car from inside out is one of the most important thing you should not avoid.

A rough running car engine is an indication that it requires a proper service. As such there could be numerous reasons why your car engine and parts such as carburetor isn’t running efficiently. To experience a smooth driving it is important that you give your car a routine check-up and maintenance, especially to the inside engine parts.

What are ultrasonic waves?

Ultrasonic cleaner waves are sound waves transmitted above 20,000 Hz (20 kHz or 20,000 cycles per second), or higher than the frequency detectable by humans. Sound waves are created by the vibration of an object, which causes the air molecules around it to vibrate. These vibrations cause our eardrums to vibrate, which the brain then interprets as sound. When the original vibration is very fast, so are the sound waves, and the pitch of the sound created is too high for the human ear to hear.

Why Clean Stainless Steel Pipe with Ultrasonics?

Delivering and using clean parts is not always obvious. Certainly, no one wants to handle a dirty part or install it into a critical machine, but dirt, debris and contaminants can cause problems for manufacturers and end users. From the merely frustrating to catastrophic, dirty parts can cause critical components to exceed tolerances and even fail damaging valuable equipment and property while contamination (everything from grease, oil and chemicals to viruses and bacteria) can seriously harm users.

Ultrasonics: The ONLY Way to Clean Stainless Steel Pipe with Confidence

Regardless of the source of the dirt or contamination, AG Ultrasonic Cleaning Systems are designed to accommodate a wide variety of uses in diverse industries. Fast, effective and efficient, our machines will allow you to clean virtually any type of part or component. The following is just a short list of the many different types of items that have been cleaned using our systems.

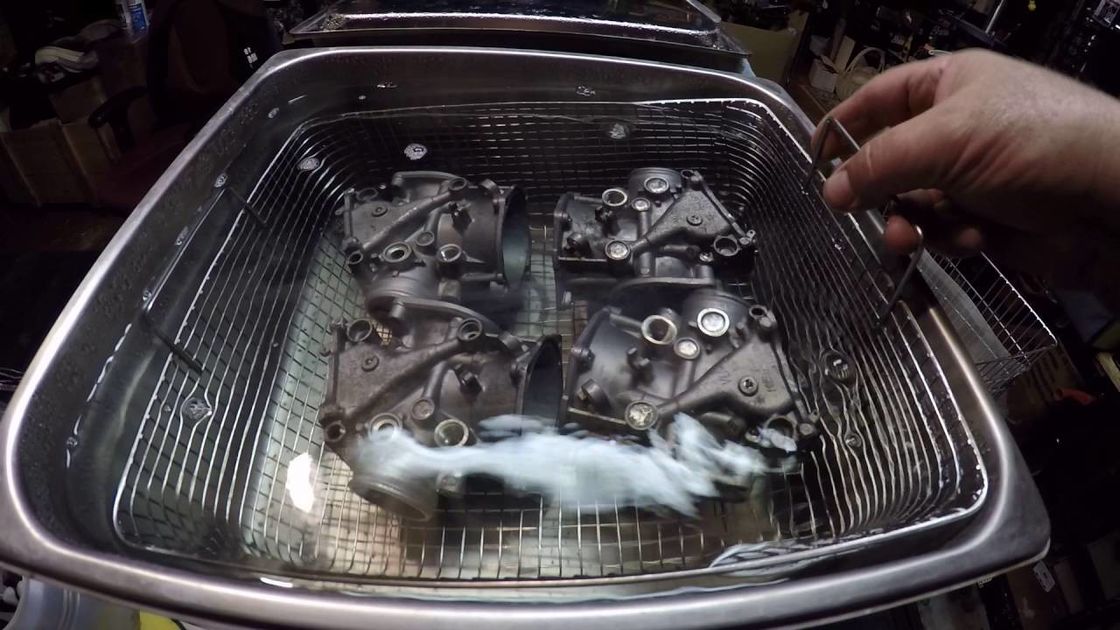

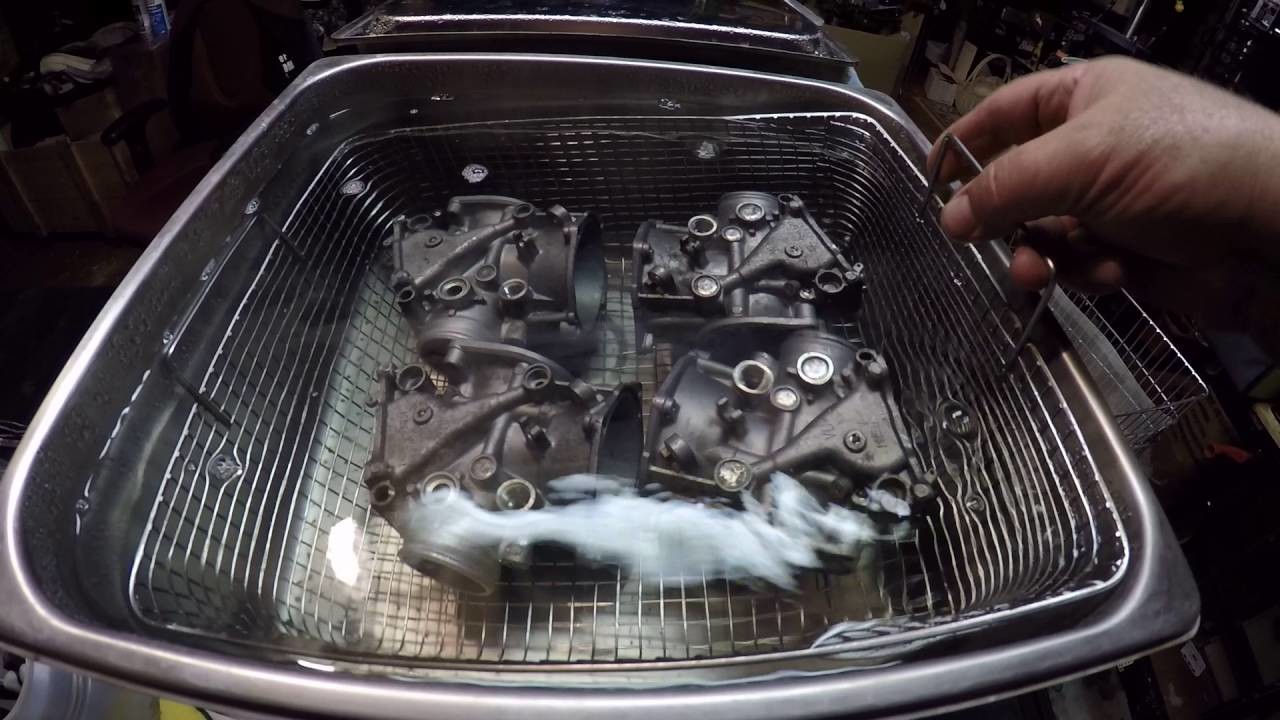

- Automotive (Car, Truck, Motorcycle) See Video Below

- Aviation (Helicopters, Aircraft and Ground Support)

- Personal Boat & Marine

- Injection Molds

- Restaurants, Bakeries & Kitchens (Oven Filters, Burners, Pots, Pans, Utensils)

- Machines of All Types

- Tools, Nuts, Bolts

- Extrusion and Deburring

- Almost anything made out of metal (ferrous and non-ferrous), plastic, vinyl, and wood.

Long Stainless Steel Round Tubes With 2 Tank Ultrasonic Cleaning And Rinsing

| Model No. |

T-2180 |

| Ultrasonic tank size(mm) |

2700x310x370mm (105” L x 12” W x 14.5”) |

| Rinsing tank size(mm) |

2700x310x370mm(105” L x 12” W x 14.5”) |

| Capacity |

310liter |

| Ultrasonic power |

4500W |

| Heating power |

9KW |

| Transducer numbers |

90pcs |

| Ultrasonic frequency |

28khz or 40khz |

| Timer |

0~30min adjustable |

| Heater |

20~80C adjustable |

| Material |

Stainless steel 304 |

| Power supply |

AC220V, 3phase , AC380V/415V 3phase |

| Optional |

Filtration system |

ultrasonic tank models for your choice:

| Model |

Tank size |

Unit size |

Volume |

Ultrasonic power |

Frequency |

Heating power |

Timer |

Heating temperature |

| LxWxH(mm) |

LxWxH(mm) |

(L) |

(W) |

(kHz) |

(KW) |

(MIN) |

(℃) |

| T-12S |

500x300x250 |

640x440x470 |

38 |

600 |

28/40 |

1.5 |

1-99 |

0-80

|

| T-18S |

500x350x350 |

640x490x570 |

61 |

900 |

1.5 |

| T-24S |

550x400x400 |

690x540x620 |

88 |

1200 |

3 |

| T-30S |

600x450x400 |

740x590x620 |

108 |

1500 |

3 |

| T-36S |

600x500x450 |

740x640x670 |

135 |

1800 |

4.5 |

| T-48S |

700x500x500 |

840x640x720 |

175 |

2400 |

6 |

| T-60S |

800x600x550 |

940x740x770 |

264 |

3000 |

7.5 |

| T-72S |

1000x600x600 |

1140x740x820 |

360 |

3600 |

9 |

Main Features

1) Tank materail is SUS304 with 2mm thickness, Human hand argon welded, Sturdy and durable resistance to high tempearture

2) 50W industrial transducers, outstanding cleaning effects

3) External ultrasonic generator

4) Power adjustable, choose different power according to different cleaning objects

5) Digital timer: 1~99hours timer adjustable. continious working for long time.

6) With memory function, no need to reset time and temperature every time.

7) 20~80C adjustable, 9KW heating panel, faster cleaning

8) Industry use power cord, more safer.

9) Can bear 50~100KG cleaning objects

10) Accessories: Machine with stainless steel basket, drainage, lid, movable castors.

AGSONIC Ultrasonic cleaning is a fast and highly efficient way for cleaning automotive parts, our equipment will remove grease, oil, lubricants and many other contaminants that are commonly found on automotive components. This includes radiators, gearboxes, inter-coolers, brake callipers, carburettors, cylinder heads, paint guns and many more.

we have supplied our ultrasonic cleaning systems to numerous Motor Racing companies, Classic Car Restorers, professional garage as well as part-time enthusiasts.

Long Stainless Steel Round Tubes Ultrasonic Cleaning

are essential parts of every heating or cooling system whether they’re used in buildings or vehicles. Radiators facilitate the transfer of thermal energy from one medium to another, allowing the regulation of air temperature in a given space. Like any HVAC part, radiators tend to accumulate dust and dirt over time. When too much debris is present in the radiator, its performance is stunted and energy efficiency is negatively impacted.

Unlike most parts of an average heater or air conditioner, the radiator can be pretty sensitive to the force applied during cleaning. Too much force can damage it while too little can allow dirt to linger inside. To strike the perfect balance between effectiveness and safety, we recommend ultrasonic cleaning for Long Stainless Steel Round Tubes

INDUSTRIAL Ultrasonic machine Introduction

Ultrasonic cleaning is a technology that uses high frequency sound waves (ultrasonic: above the range of human hearing) to agitate an aqueous or organic medium (cleaning chemistry) that in turn acts on contaminations adhering to substrates like metals, plastics, glass, rubber and ceramics. Contaminants can be dust, dirty, oil, pigments, grease, polishing compounds, flux agents, fingerprints, soot wax and mold release agents, biological soil like blood, and so on

Why Use AGSONIC’s Ultrasonic Cleaning Systems?

- Rapid cleaning – saving time and money

- Effective process – flexible wash, rinse and dry systems delivering the perfect results

- Complete Clean – reach intricate parts that spray wash systems and manual cleaning cannot achieve

- Increase productivity – fast, high quality cleaning results the first time round

- Eliminate manual scrubbing – one button press, operators can spend time completing other tasks

- Green – clean and degrease with water based detergents. No solvent use, improving operator safety

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!