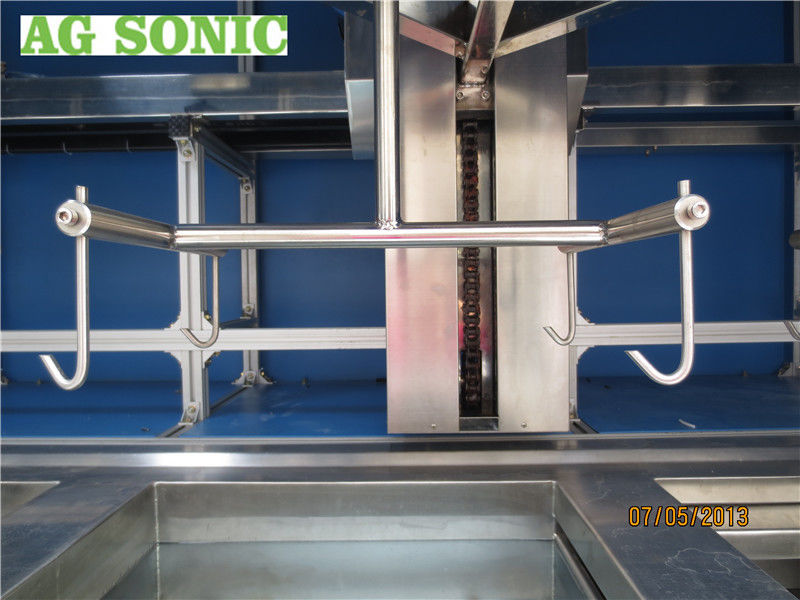

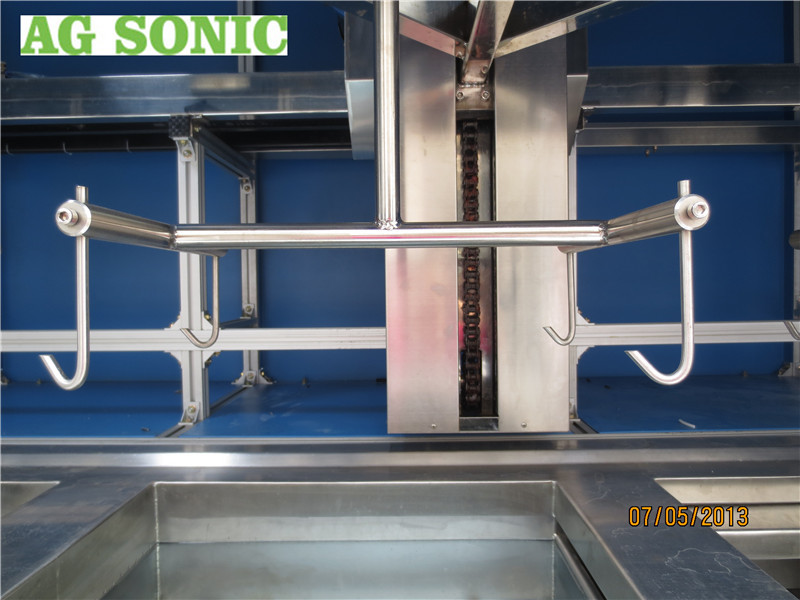

Mechanical Arm Full-Automatic Cleaner Ultrasonic Disinfect Drying For Medical Instrument

MULTISTAGE AUTOMATIC SMART LINE

AG Sonic has designed a standardised line both in capacity and in cleaning or treatment stages. Since the requirements for quality and quantity of the parts to be cleaned are different, each cleaning system is built accordingly, bearing in mind the production and features of such piece.

The Automatic Smart series are fully automated systems with a load capacity ranging from 20 to 100 Kg. This equipment is designed to meet the highest requirements for industrial cleaning, there by achieving cleaning results that meet the requirements and standards demanded by our customers.

Arm Full-Automatic Cleaner Ultrasonic Specification

| Model |

T-5024S |

| 1st -5tanks Tank Volume |

77L |

| First -5tank size |

550X400X350mm |

| Transducers |

24pcs 50W of every transducer |

| Ultrasonic Power |

1200W |

| Heating Power of Ultrasonic tank |

3000W |

| Heating Power of Drying tank |

750W |

| Frequency |

28KHz/40KHz |

| Drying System |

1 set connected with 2d tank |

| Filtration cycle system |

1 set connected with 1st tank |

| Unit size |

1550*1050*950mm |

| Packing size |

1610*1110*1070mm |

| Timer |

0~99 minutes adjustable |

| Heater |

Room temperature~99℃ adjustable |

| Material |

SUS 304 default, can be SUS 316 |

| Power Supply |

AC 220V 3 phase ; AC 380V 3 phase |

| N.W. |

230G |

| G.W. |

260KG Wrapped by film in wooden case |

| Lead time |

18 working days |

| Warranty |

1 year warranty period, technique support all time |

| Certificates |

CE, RoHS, FCC, |

| Advantage |

Filter the dirty water; keep the water clear in tank; lower the frequency of changing water |

Optional

Pneumatic or hydraulic platform lift for parts swing to increase effectiveness while cleaning or rinsing stages.

Cartridge or bag filtration for ultrasonic tank.

Automatic water refilling.

Automatic Liquid Detergent Dosing System .

Detergent preparation (pre-mix) tank.

Automatic Oil Separation for US tank.

Air bubbling or water jets for rinsing tanks.

Active carbon filtering for rinsing stages.

Sprinklers system for parts rinsing while being extracted.

Osmosis plant for demineralized water generation for final rinsing stages.

Safety enclosure for loading system.

Customized basket and lifting beams.

Steam extraction to ensure healthy plant environment.

Loading/unloading conveyors, manual or motorized.

Ultrasonic sets at rinsing stages for special applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!