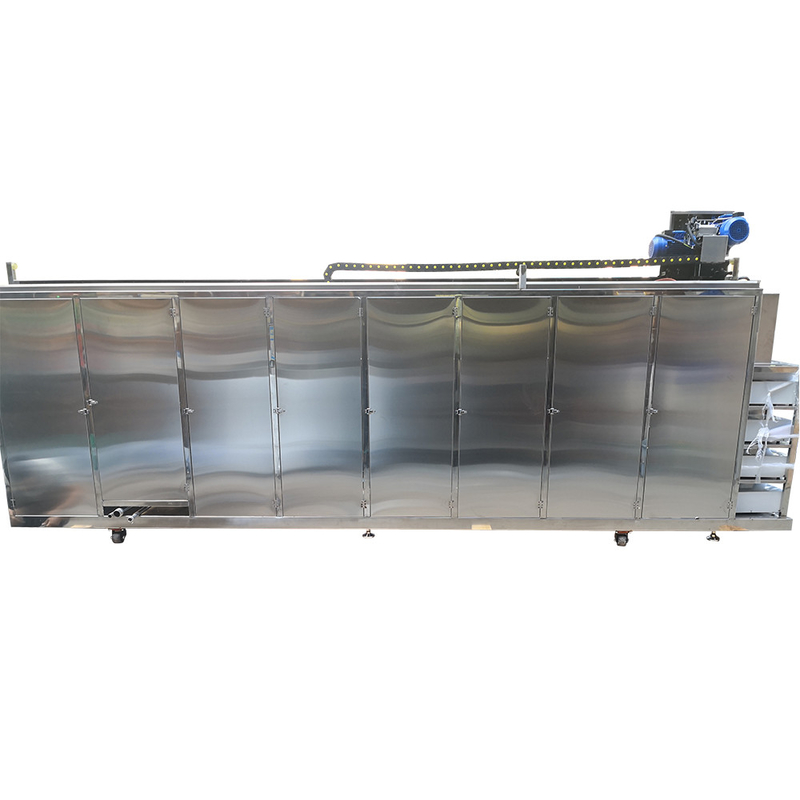

Full Automatic Ultrasonic Cleaning Machine Optic Manufacturers Cleaning Of Spectacles

Automatic pass-through spray ultrasonic cleaning machine

1. Features (automatic, cleaning, spraying, rinsing, drying)

1. It adopts fully automatic single-arm manipulator to move, which is stable, reliable and high in accuracy.

2. High-pressure spray cleaning uses clean water to spray from the bottom and wash the remaining cleaning fluid and stains from all sides for further cleaning

3. The drying system uses hot air circulation drying, which is effective for rapid drying and rust prevention.

4. The cleaning tank has its own filter system, which effectively saves the frequency of replacing the cleaning fluid and saves costs.

5. Automatic constant temperature, automatic liquid level control system.

6. Use water-based neutral cleaning agent, city water or pure water to clean.

7. The whole process is made of stainless steel, with beautiful appearance.

Washing process: Spray cleaning → Spray rinse→ Compressed air blow water → hot air drying → Oiling

Cleaning medium: water based

Ultrasonic washing machine device usage:

As per required cleanliness degree, determine a reasonable way of ultrasonic cleaning, technical process, safety procedures, quality control procedures, cleaner agent replacement cycle.

1. Ultrasonic cleaning:

a. Put determined cleaning agent into ultrasonic cleaning tank, and stir well.

b. Put to be cleaned plating parts in an ultrasonic special cleaning basket then into ultrasonic cleaning tank.

c. After 3-5 minutes of ultrasonic washing, then rinse, wash, rinse with pure water, or dried.

d. Follow-up plating technical process according set procedure.

2. Spray (ultrasonic) cleaning:

Full-Automatic Cleaner Specification

| Heating power |

Constant temperature heating |

| Voltage/Power Supply |

220v/380v/415v/440v optional |

| Material |

Stainless steel 316 / 304 |

| Ultrasonic directions |

Three sides or down side |

| Control |

PLC |

| Ultrasonic frequency |

28khz/40khz/60khz optional |

| Single tank capacity |

40L,60L,80L,100L,130L,200L,308L,500L,760L Customized |

| Optional function |

Ultrasonic clean/rinsing/ spraying/ drying/ cooling |

| Cleaning process |

Washing process: Spray cleaning → Spray rinse→ Ultrasonic cleaning → hot air drying → Oiling

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!