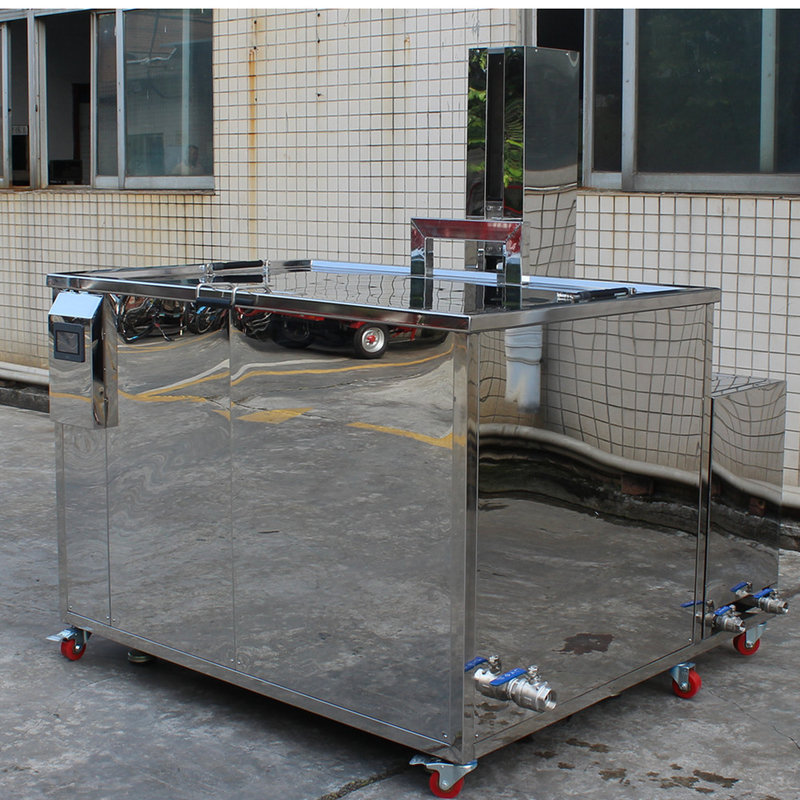

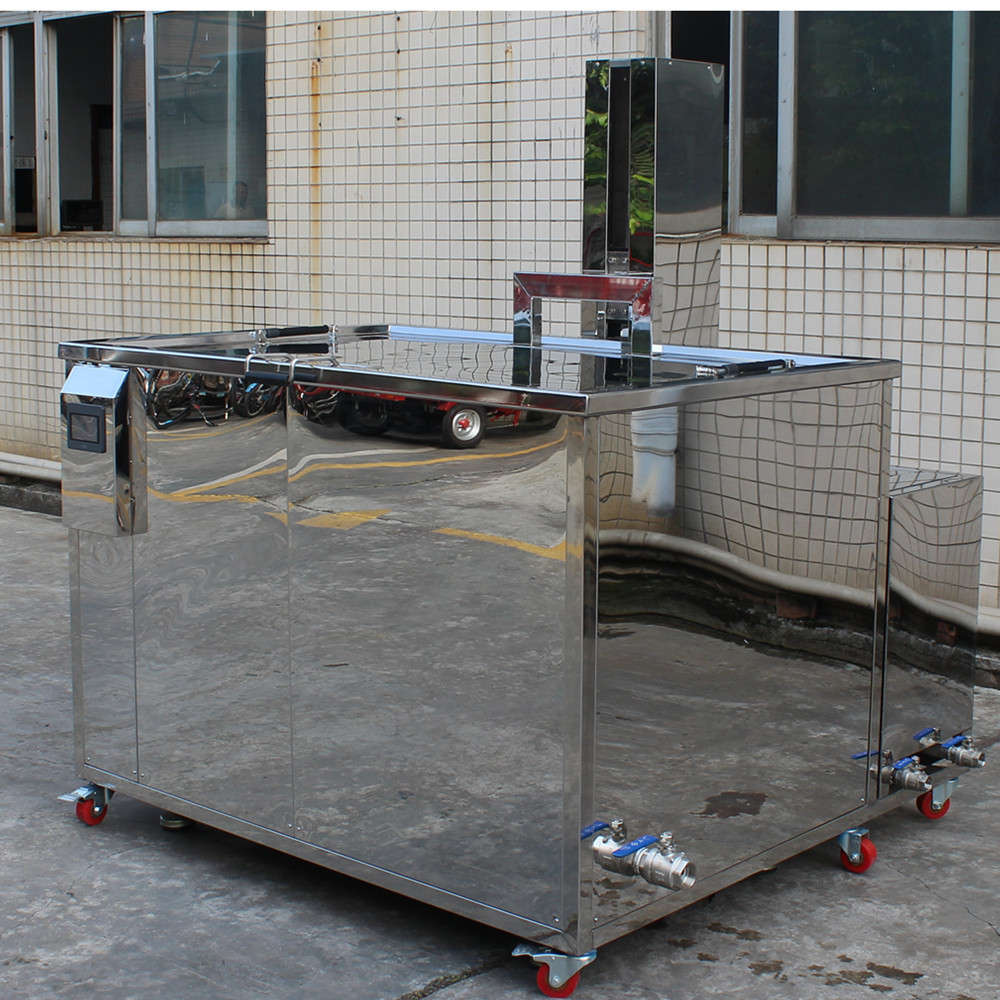

Industrial Injector Automotive Ultrasonic Cleaner For Automatic Precision Metal Parts

Industrial Injector Ultrasonic Washing Cleaner with Auto Lift for Automatic Precision Metal Parts

Ultrasonic Cleaner Auto Industry

We are the manufacturers of custom built Ultrasonic Cleaning machines for degreasing and cleaning of auto parts for OEMs , work shops , job works and auto-restoration industry. We expertise in providing customized designed solution for auto parts cleaning.

Ultrasonic cleaning is a water based cleaning solution where ultrasonic transducers are used to provide cavitation agigation insude the tank which has waer and suitable chemical to clean oil,dirt,debree,grease and other contaminants from various types of auto components.

We expertise in all types of ancilary parts washing like brakepads, steering coloumns, crank shats, pistons, valves, gaskets, clutch pads, mirrors and many more.

Features of the machine:

• Low maintainence machine

• Heavy duty cleaning systems

• Chemical friendly- SS Rust proof body

• Industrial guage farication, build to last

• One year warrenty on any manufacturing defect

• Completely customized to suit the cleaning requirement

• Less human interfearance and less scope of error

• Accurate and uniform cleaning everytime

Automotive Ultrasonic Cleaners

For small autoparts such as plugs, screws, bolts, hex and fixtures, SS ball bearings and components with less than 100 mm length, we suggest a small ultrasonic autoparts cleaner which has a capacity of 4-5 Liters of water and can clean upto a kg of material within 3-30 minutes depending upon the component type and contamination load.

Ultrasonic cleaning machines work on the principle of agitating cleaning solvents using high frequency sound waves, the ultrasonic agitation creates millions of microscopic bubbles that implode releasing vast quantities of energy, this action, know as cavitations, dislodges any contaminant stuck to the surface of a part, ultrasonic cavitations thoroughly cleans every surface in contact with the cleaning fluid

Multi Stage Aqueous Ultrasonic Cleaners

Why Use Ultrasonic Cleaner

The current practice involves use of chlorinated solvents like TCE, PCE etc. that are the choice solvent used through the industries in their cleaning process. Aqueous Ultrasonic Cleaning System are very popular due to their good solvency, lower heat of evaporation, high or absence of flash point, non-corrosive nature, relative stability & compatibility with metals & glass. However all chlorinated solvents are hazardous to human health & environment.Some chlorinated solvents are suspected to cause cancer (Carcinogenic) over prolong exposure. Being hazardous to health their usage has come under intense investigation from pollution control & health authorities & has already been banned by developed countries. This has lead to shift to alternative cleaning technology based on aqueous solvents.

We are one of the leading manufacturers and suppliers of an array of Semi Automatic Cleaning Systems. Known for their low noise and smooth operation, these are widely considered among the customers we have. Available in different types depending upon the production rate, these conveyors are acknowledged for high load bearing capacity and sturdy construction. We also undertake customization of this range to meet the specific requirements of our clients. Depending on the cleaning level required the number of cleaning stages are decided.

We expertise in Multistage Cleaning Systems with Multiple tanks having Ultrasonic, Jet Spray, Rotating Basket, Dunking, Automatic Material Transfer, Handling system, Filtration, Oil Skimming & Drying as various options. Such machine are used for cleaning of Mold Inserts, Auto-Ancillary Parts, Medical Surgical tools and various other types of components.

Multistage Ultrasonic Cleaning Machine with the ultrasonic power. The product comes with digital timer and controlled thermostat. We offer a unique range of ultrasonic cleaning machines that are highly demanded for their excellent performance and low maintenance. Ultrasonic cleaner is majorly used in cleaning surgical instruments, automobile industry, ancillary industrial products, stationary manufacturers and many more.

Model:

ultrasonic tank models for your choice:

Specifications:

| Model |

T-3048G |

T-3072G |

T-3144G |

| Ultrasonic Tank Dimension(mm) |

550X400X350 |

600X500X450 |

1000X600X600 |

| Rinsing tank dimension(mm) |

550X400X350 |

600X500X450 |

1000X600X600 |

| Drying tank dimension(mm) |

550X400X350 |

600X500X450 |

1000X600X600 |

| Max. Capacity |

77L/tank |

135L/tank |

360L/tank |

| Construction Case |

SUS304 (Mirror shining image available) |

| Construnction Tank |

SUS304 |

| Transducer Number |

48pcs |

72pcs |

144pcs |

| Ultrasonic power(Max.) |

2400W |

3600W |

7200W |

| Ultrasonic frequency |

40kHz |

40kHz |

40kHz |

| Temperature range |

20~80C adjustable |

|

|

| Heating power |

6KW |

12KW |

24KW |

| Timer |

1~99h |

1~99h |

1~99h |

| Drain |

3/4" Valve |

|

|

| Lid & Basket |

Available, material: SUS304 |

|

|

| Cleaning Tank voltage |

AC220V/AC380V 3phase |

|

|

| Generator Voltage |

AC110V / 220V 1phase |

|

|

| Features |

With triple tanks for cleaning and rinsing.

With filtration system

Multi-direction castors with brake;

1 year warranty |

RFQ:

How do I get the best ultrasonic cleaning?

There are many considerations important to ultrasonic cleaning. Optimising these variables will produce the best cleaning. The most important decisions to be made are choosing the proper cleaning solution, cleaning at the right temperature for the correct amount of time, and choosing the right size and type of ultrasonic cleaner.

Is a special solution required for cleaning?

Soils adhere to the parts... if they didn't, the soil would just fall off the parts! The purpose of the solution is to break the bonds between parts and their soils. Water alone has no cleaning properties. The primary purpose of the ultrasonic activity (cavitation) is to assist the solution in doing its job. An ultrasonic cleaning solution contains various ingredients designed to optimise the ultrasonic cleaning process. For example, increased cavitation levels result from reduced fluid surface tension. An ultrasonic solution will contain a good wetting agent or surfactant.

What is Ultrasonic Cleaning

In a process termed "cavitation", micron-size bubbles form and grow due to alternating positive and negative pressure waves in a solution. The bubbles subjected to these alternating pressure waves continue to grow until they reach resonant size. Just prior to the bubble implosion, there is a tremendous amount of energy stored inside the bubble itself. Temperature inside a cavitating bubble can be extremely high, with pressures up to 500 atm. The implosion event, when it occurs near a hard surface, changes the bubble into a suction jet about one-tenth the bubble size, which travels at speeds up to 400 km/hr away from the hard surface. With the combination of pressure, temperature, and velocity, the jet frees contaminants from their bonds with the substrate. Because of the inherently small size of the jet and the relatively large energy, ultrasonic cleaning has the ability to reach into small crevices and remove entrapped soils very effectively.

What is cavitation?

"Cavitation" is the rapid formation and collapse of millions of tiny bubbles (or cavities) in a liquid. Cavitation is produced by the alternating high and low pressure waves generated by high frequency (ultrasonic) sound. During the low pressure phase, these bubbles grow from microscopic size until, during the high pressure phase where they are compressed and implode.

How the System Operates:

The system operates in the following manner:

- Parts are placed into the tank using the included stainless steel basket or other holding fixture.

- Once submerged, the START button is pressed, and the cover is closed. The ultrasonic system turns on, and the filter system turns off automatically. Parts are cleaned with the CROSSFIRE ultrasonic system at this time.

- The system will automatically turn off upon completion of the cycle.

- Operators can then return when the parts are clean.

The cover is opened and the batch of parts is placed onto the basket rest. Dripping liquids are directed back to the ultrasonic cleaning tank

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!